In 1958 oil was discovered 150 kms off the coast of Abu Dhabi and triggered off a glorious history for Oil & Gas in UAE. In the 1970’s H.H. Sheikh Zayed bin Sultan Al-Nahyan, the late President & Founder of the UAE, was deeply concerned about the wastage of natural resources and its adverse effects to the environment due to unnecessary flaring of natural gases. In 1972, an agreement was signed with Tokyo Electric Power Company (TEPCO, now a part of JERA) to supply LNG and LPG over 20 years. In 1973, Abu Dhabi Gas Liquefaction Co. Limited (ADGAS) was founded to realise the Sheikh’s lofty vision, with ADNOC (Abu Dhabi National Oil Company), Mitsui & Co. Ltd, BP, Total and Bridgestone as shareholders.

Das Island, a 2.5 square kms island, 150 kms off the coast of UAE, was selected as the ideal site for construction of the LNG plant. The strategic location provided ADGAS ease of access to growing markets in Middle East, Asia and Europe. The first 2 trains were commissioned in 1977, with first cargo being dispatched from the plant on April 29th, 1977. ADGAS became the pioneer of the gas liquefaction industry in the Middle East and North Africa (MENA) region.

In 1990, ADGAS signed a new agreement with TEPCO to supply double the quantity of LNG for 25 years starting 1994. This necessitated construction of a third and larger LNG train at the facility. With the new train starting production in 1994, ADGAS LNG upped its capacity to 8 MMTPA. In 1997, for the first time the plant sold more than 8 million tonnes of LNG in one calendar year. By late 2005, the project had already processed 100 million tonne of LNG and the very next year a safety milestone of 25 million man-hours without a Lost Time Injury (LTI) was achieved. In October 2017, ADNOC consolidated all its subsidiaries under one parent brand umbrella, rechristening ADGAS LNG to ADNOC LNG.1

In November 2018, the gas supply agreement to the plant was extended to 2040 with effect from 1st April 2019. The plant has a unique ability to process both associated and non-associated gases at high as well as low pressures. ADNOC LNG receives associated gas from the Umm Shaif, Zakum and Bunduq oilfields, and natural gas from the Abu Al BukhooshKuff, Uweinat, Areaj and Umm ShaifKhuff oilfields, as well as the cap gas fields.2 The facility processes and produces LNG, LPG, paraffinic naphtha and sulphur in addition to supplying one billion standard cubic feet of gas per day to the UAE’s national grid.

ADNOC is deeply concerned about the welfare of the local community and has invested in development of roads, hospitals, schools and mosques, in addition to funding the Ministry of Labour and Social Affairs, Emirates Red Crescent, Khalifa Foundation and various local sports and cultural clubs. In 2008, the ADNOC Schools were founded, which enrol 6000 students into its 4 campuses. The ADNOC Technical Institute (ATI) was established in 1978 and has skilled more than 3500 UAE nationals as oil and gas technicians. Since 1974, ADNOC has supported a scholarship program for post-secondary education of UAE nationals around the world. ADNOC LNG prides its proactive approach towards environmental protection and have successfully committed to reducing flaring and emissions, which formed the foundation of the company.

OWNERSHIP (Equity %)

| Abu Dhabi National Oil Company (ADNOC) | 70.00% |

| Mitsui | 15.00% |

| British Petroleum (BP) | 10.00% |

| Total | 5.00% |

General Data

| Estimated Capital Cost (USD) | NA |

| Plant Type | Onshore |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 1972 |

| FEED Contractor | Chiyoda Corporation |

| EPC Contractor | Chiyoda Corporation |

| No. of Trains / capacity | 2 Trains / 1.3 MMTPA each |

| Production Start Year | 1977 |

| Products | LNG, LPG, Condensate, Propane, Butane |

| Gas Type | Associated and Non-Associated Gas |

Technical Data

| Cooling Media | Seawater |

| Liquefaction Technology | APCI AP-C3MR™ |

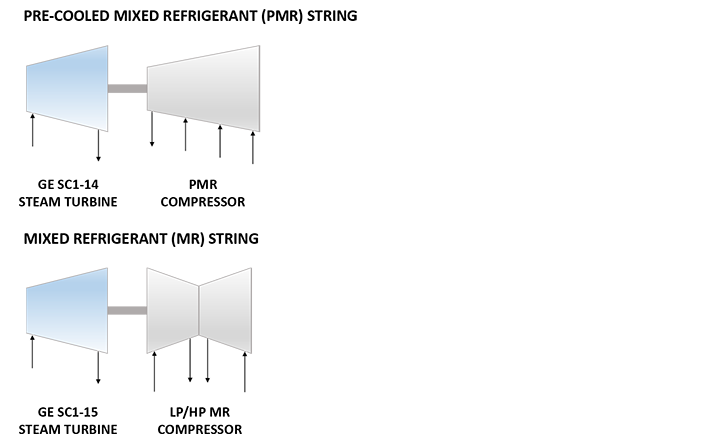

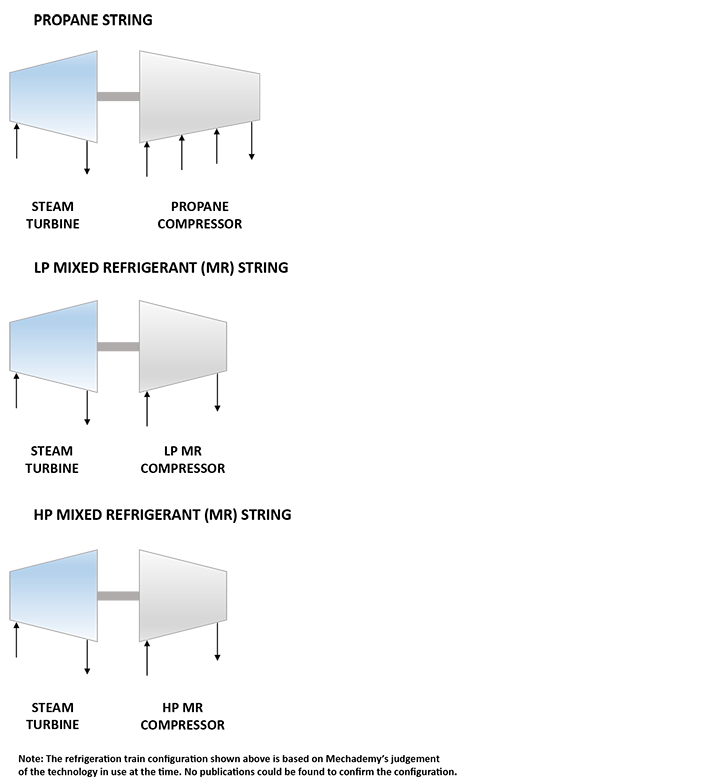

| Refrigeration Train Details: | |

| Propane String | |

| Driver | Steam Turbine |

| Propane Compressor | Carrier Corporation (Elliott) Horizontally Split Centrifugal Compressor |

| Low Pressure (LP) Mixed Refrigerant (MR) String | |

| Driver | Steam Turbine |

| LP MR Compressor | Horizontally Split Centrifugal Compressor |

| HP Mixed Refrigerant (MR) String | |

| Driver | Steam Turbine |

| HP MR Compressor | Radially Split Centrifugal Compressor |

| Power Generation | Trains 1-3 2 x Steam Turbine Generators (17.5 MW) 4 x Gas Turbine Generators (17.5 MW) |

Refrigeration Train Configuration

Key Facts

- In March 1978, ADGAS witnessed a failure in a bottom pipe connection of a double walled LNG tank. The accident formed a large heavier-than-air cloud of vapor from the outer shell of the tank, which did not ignite.3

- In 2018, Japan’s JERA signed an agreement with ADNOC LNG to purchase as many as 8 cargoes per year. This translates to approximately 0.5 MMTPA of LNG. The 3 year deal will cover deliveries from April 2019 to March 2022, on a delivered-ex-ship (DES) basis.4

- Tokyo Electrical Power Company (TEPCO) is ADGAS’ main customer. For almost four decades, most of ADGAS’ gas production has been supplied to TEPCO for power generation.5

- Since 2009, ADNOC has dramatically reduced flaring and volume of emissions by 57%. In 2011, a flare handling and reduction scheme was successfully implemented to reutilize flared gas and reduce CO2 emissions. This resulted not only in improving ambient air quality but also provided economic savings.5

- ADNOC LNG feeds on sour gas, containing significant quantities of acidic gases such as hydrogen sulfide (H2S) and carbon dioxide (CO2). Accordingly, the emissions from the plant can potentially deteriorate the ambient air quality on the Island and affect the health of its residents. Two schemes were proposed to reduce the SO2 emissions by almost 77% ; a Flue Gas Desulfurization (FGD) scheme and a Fuel Gas Sweetening scheme.6,7

Source:

1. ‘Notification’, ADNOC Website

2. ‘ADGAS Corporate Profile – 25th Anniversary’, Prose Solutions

3. ‘History of accidents in the LNG industry’, La’oHamutuk Website, February 2008

4. ‘JERA signs supply deal with ADNOC LNG’, LNG World News Website, 8 August 2018

5. ‘ADGAS Corporate Profile 2014’, Group Origin Website

6. Peavy H.S. et al. ‘Environmental Engineering’, McGraw Hill Education ISBN #0070491348, 1985

7. Abu-EishahS.I. et al. ‘Minimization of SO2 Emissions at ADGAS (Das Island, UAE): I- Current vs. Modified Schemes’, Journal of Petroleum & Environmental Biotechnology (JPEB) Volume 5, Issue 2, 1000173,ISSN: 2157-7463, 25 April2014