Marsa el Brega in Al Wahat District of Libya was a quiet fishing village on the Mediterranean Sea. The development of the Brega complex, transformed the area into a bustling port and a major hub for Libyan oil & gas. Esso’s (now ExxonMobil) proposal of an LNG plant to harness gas supplied from fields in the Sirte Basin, was attested by sale agreements with Spanish and Italian customers in 1965. Several delays in construction of the plant pushed the commencement of commercial operation to 1971. The plant was the first in the world to use APCI’s single mixed refrigerant (SMR) technology, making Libya the third country in the world to export LNG.

In early 1980’s sanctions imposed on Libya crippled the exports from the plant and resulted in the exit of Esso from the project. The sanctions also prevented Libya from upgrading its LNG technology to strip LPG from feedgas, thus limiting its LNG exports to just one Spanish facility operated by Enagas.1 In 2005, once the sanctions were relaxed, the Sirte Oil Company (subsidiary of National Oil Corporation) signed a $643 million contract with Shell for the restoration and expansion of Marsa el Brega LNG.2 Internal political unrest in the region followed by the Libyan civil war in 2011, resulted in severe damage to the complex. Shell exited the country in May 2011 and the plant remains out of operation ever since.

Reportedly, Libya doesn’t have specific government regulations or environmental guidelines for LNG plants. The plant technology doesn’t conform to current safety standards, nor are the facilities suitable for modern large capacity LNG carriers. In addition, the equipment and infrastructure may already be at the end of its design life. Substantial renovations and upgrades are therefore critical to return the plant to operation. A proposal has also been made to convert the liquefaction facility into a regassification facility to meet local gas demand.3

OWNERSHIP (Equity %)

| Sirte Oil Company, a subsidiary of Libya National Oil Company (NOC) | 100.00% |

General Data

| Estimated Capital Cost (USD) | Not Available |

| Plant Type | Onshore, Stick-built |

| Plant Stage | Non-operational since 2011 |

| Final Investment Decision (FID) Year | 1965 |

| FEED Contractor | Not Available |

| EPC Contractor | Saipem (Construction) |

| No. of Trains / capacity | 4 / 0.8 MTPA per train |

| Production Start Year | 1970 |

| Products | LNG |

| Gas Type | Non-Associated Gas |

Technical Data

| Cooling Media | Seawater |

| Liquefaction Technology | APCI AP-SMR™ (First APCI Technology LNG Plant) |

| Refrigeration Train Details: | |

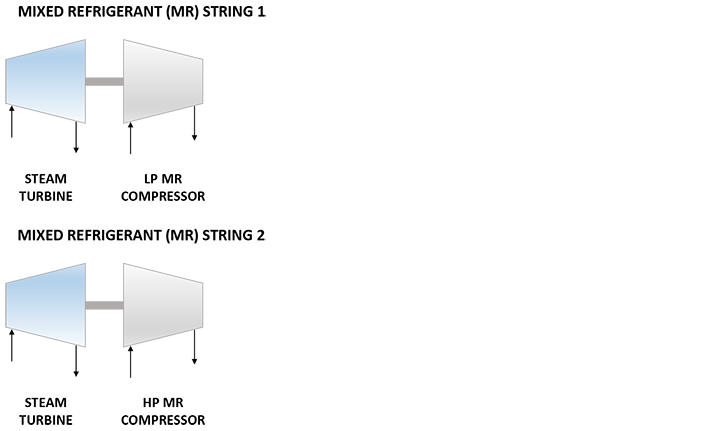

| Mixed Refrigerant (MR) String 1 | |

| Driver | Steam Turbine |

| Low Pressure (LP) MR Compressor | Carrier Corporation (Elliott) Centrifugal Compressor |

| Mixed Refrigerant String 2 | |

| Driver | Steam Turbine |

| High Pressure (HP) MR Compressor | Carrier Corporation (Elliott) Centrifugal Compressor |

Refrigeration Train Configuration

Key Facts

- Marsa el Brega was the first ever application of the single mixed refrigerant cycle (SMR) liquefaction technology designed by Air Products and Chemicals International (APCI). The two previous LNG plants had utilized 3-cycle cascade processes with single component refrigerants. It was also the first LNG plant to use a coil-wound main cryogenic heat exchanger. A four-bundle design was utilized.

- It was the world’s first LNG plant to use a coil-wound (spiral wound) main cryogenic heat exchanger. A four-bundle design was utilized.

- Marsa el Brega lacks the capacity to strip liquid petroleum gas (LPG) from its feed gas and therefore produces an LNG that is not compatible with global standards. This severely limited its market with most of its LNG shipped to a single Spanish regasification train run by Enagas.1

- From an environmental standpoint, the plant does not conform to currently acceptable international standards, some major issues include:

> Spent caustic from the plant is discharged directly into the sea

> Hydrogen Sulphide (H2S) removed from the feed gas in the acid gas treatment unit is vented directly to the atmosphere

> Boil off gas from the LNG tanks is vented directly to the atmosphere

> Treatment of process water streams targeting the removal of hydrocarbons is inadequateThese deficiencies were recognized by the plant and a joint rejuvenation project with Shell had been planned to address these deficiencies along with making several other upgrades.2 - In May 2005, the Libyan National Oil Company (NOC) reached an Agreement with Shell which, in addition to granting Shell exploration rights covering some 20,000 square kilometers of acreage in the Sirte basin, included a commitment to rejuvenate the Brega plant and to restore its nameplate capacity of 3.2 MMTPA from its diminished capacity of 0.7 MMTPA. At the time, the plant had not been rejuvenated in its 35 years of operational life. However, the rejuvenation of the LNG Plant fell through following the 2011 Arab Spring and subsequent civil war.2

- As of December 2018, the Marsa el Brega plant remains suspended due to the Libyan Civil War. It repeatedly changed hands between Gaddafi and rebel forces in the 2011 war and the complex was badly damaged. Gaddafi forces destroyed at least four oil storage tanks, while NATO bombed the complex clubhouse, a communications tower and other facilities after learning that they were being used to store weapons. Upon fleeing the complex after the fall of Tripoli in late August, Gaddafi loyalists reportedly also left behind 40,000 anti-personnel and anti-tank mines around the town of Brega and 6,000 mines on a nearby beach.4

Source:

1. https://ihsmarkit.com/country-industry-forecasting.html?ID=106593720

2. Bouaziz M., et al ‘Libya LNG – Rejuvenating Brega and Developing New LNG’, PS5-5.1

3. http://documents.worldbank.org/curated/en/864771527060164822/pdf/02-Task-B-Libya-LNG-Import-Options-Report-R4-clean.pdf

4. Multiple Sources:

• http://wiki.openoil.net/Brega_Complex#cite_note-8;

• https://en.trend.az/other/commentary/2970968.html