On May 17, 1989 Nigeria LNG Limited was established to tap Nigeria’s abundant natural gas resources and monetise it through LNG exports. Final Investment Decision (FID) for the first 2 trains was signed in November 1995. Construction started on 2.27 square kilometre of mostly reclaimed land at Finima, Bonny Island in 1996. Train 2 was the first to be set for start-up and production was underway in September 1999. Train 1 was started in February 2000.

Riding on the success of the 2 trains, subsequent expansion plans were deployed rapidly. Train 3 received FID in February 1999 and came on stream in November 2002. Under the NLNG Plus project, construction of 2 additional trains was initiated in March 2002, leading to Train 4 commencing operation in November 2005 and Train 5 joining in by February 2006. The NLNG Six project included construction of a condensate processing and LPG storage facility in addition to the added capacity of Train 6, which commenced operations in December 2007.

The plant boasts of a diversified gas supply (Associated Gas & Non-Associated Gas) and six main dedicated gas transmission pipelines with four of them on-shore. The 3.5 billion Bcf/day feed to the plant is supplied through long term Gas Supply Agreements (GSAs) with Shell Petroleum Development Company of Nigeria Limited (SPDC), Total Exploration Production Nigeria (TEPNG) and Nigerian Agip Oil Company Limited (NAOC). With aninvestment of $9.35 billion, the NLNG project consists of 6 liquefaction trains, 4 LNG storage tanks, 3 condensate storage tanks, 4 LPG refrigerated storage tanks and 10 gas turbine generators with a combined output of 320 MW. 23 LNG vessels visit the 2 export jetties at the facility, which handles over 400 loadings per year. By May 2017 the plant had already shipped its 4000th cargo.

16 long term LNG Sales Purchase Agreements (SPAs) with 11 buyers consume the plant’s capacity of 22 MMTPA LNG in addition to 5 MMTPA NGL’s (LPG and condensate). The list of buyers includes Enel, Gas Natural, Botas, GDF Suez, GALP Gas Natural, BG LNG, Endesa, ENI, Iberdrola, Shell Western LNG BV and Total Gas and Power Ltd. Recent signing of a 20-year SPA with Total has prompted progress on the plans for the next phase of expansion. Addition of Train 7 is anticipated to enhance the total production capacity to over 30 MMTPA of LNG.

Each construction year generated in excess of 2000 jobs, while 18,000 locals were hired by the major sub-contractors for technical jobs in the base project. The company has initiated the Nigerianisation scheme, under which the company recruits, trains and develops skills of Nigerians for management, supervisory and operational positions in the company. NLNG’s social commitment extends to a range of other activities including health schemes, electricity generation, construction of roads, water projects and building educational infrastructure.

The company has initiated social welfare programs such as the Youth Empowerment Scheme (YES), the Nigeria LNG Agro Development Action (N- AGENDA), the Nigeria Prizes, NLNG University Scheme Programme, Micro-Credit etc. Over 200,000 residents receive uninterrupted power from NLNG Limited. NLNG has created a nature park on over 1000 hectares on Bonny Island with the view to preserve the natural environment of its host communities. Gas consumed by the plant helps in reducing flaring by upstream operators from 60% to below 25%.

OWNERSHIP (Equity %)

| Nigerian National Petroleum Corp. (NNPC) | 49.00% |

| Shell | 25.60% |

| Total | 15.00% |

| Eni | 10.40% |

General Data

| Estimated Capital Cost (USD) | 4.0 B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | Train 4 & 5 – 2002 Train 6 – 2004 |

| FEED Contractor | KBR |

| EPC Contractor | Technip Snamprogetti KBR (formerly, M.W. Kellogg) Japan Gas Corporation |

| No. of Trains / capacity | 3 Trains / 4.1 MMTPA each |

| Production Start Year | 2006 (Train 4) 2006 (Train 5) 2008 (Train 6) |

| Products | LNG, LPG, Propane, Butane & Condensate |

| Gas Type | Associated & Non-Associated Gas |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | APCI AP-C3MR™ |

| Refrigeration Train Details: | |

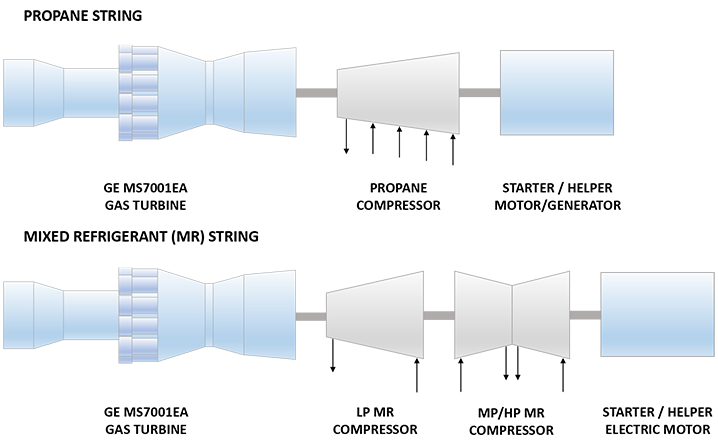

| Propane String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | 3MCL1405 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | 15 MW Converteam (GE) Induction Motor with MV7000 VSI Drive |

| Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) MR Compressor | AN200 GE (Nuovo Pignone) Axial Compressor |

| Medium Pressure (MP) / High Pressure (HP) MR Compressor | 2BCL806 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | 15 MW Converteam (GE) Induction Motor with MV7000 VSI Drive |

| Power Generation | 4 x GE PG6581B (Frame 6B) Heavy Duty Gas Turbines (Added to existing 6 x GE PG6581B units) |

Refrigeration Train Configuration

Key Facts

- Nigeria has the largest proven natural gas reserves in Africa and the ninth largest in the world.1

- Despite a substantial reduction in natural gas flaring due to liquefaction of the gas at Nigeria LNG, Nigeria still flares the second largest amount of natural gas in the world, following Russia.1

- Trains 4-6 were designed with a significantly higher LNG capacity of 4.1 MMTPA compared with Trains 1-3 (2.9 MMTPA). The design incorporated several significant technical changes including: 10

> Trains 4-6 are air-cooled (vs water-cooled)

> The propane compressors are driven by GE Frame 7EA gas turbines (vs GE Frame 6B)

> Power can be exported from the propane helper motors

> The LNG trains operate at a higher pressure compared with Trains 1-3

> The Frame 7EAs have DLN1 combustors (vs standard combustors)

> Waste Heat is recovered from the propane compressor gas turbine exhaust stack

> The trains have an Extended End Flash System

> Spent Amine can be incinerated in the acid gas - Train 6 additional scope of work included an upgrade of the electrical network to 132kV; one 84,200m³ LNG tank; one butane and one propane tank, each 65,000m³; and one condensate tank 36,000m³.7

- For Trains 4-5, Siemens supplied the world’s largest end-flash gas (EFG) single shaft compressor at the time. The compressor has a 900 mm impeller diameter, inlet guide vane (IGV) controls and dry gas seals encapsulated in a heated seal carrier.11

- In 2012, after a fire incident resulted in degraded performance of one of Nigeria LNG’s Frame 7EA gas turbines, Nigeria LNG in partnership with GE Oil & Gas executed Africa’s first flange-to-flange replacement (engine swap out) of a heavy-duty gas turbine.12

- In 2013, NLNG had to incur significant lost revenue due to a 3-week blockade imposed on its ships by the Nigerian Maritime Administration and Safety Agency (NIMASA) due to a tax dispute. NLNG eventually agreed to pay a levy “under protest”. The two sides settled on a payment of USD 140 million and the blockade was lifted in July 2013.8

- In 2007, the front-end engineering and design (FEED) contract for Train 7 expansion was awarded to the TSKJ consortium (Technip, Snamprogetti Netherlands, KBR and JGC Corporation). However, the project was stalled due to a bribery scandal which ultimately resulted in several of the contractors paying large fines to settle criminal and civil FCPA charges brought by the U.S. Department of Justice. 5

- In July 2018 NLNG awarded fresh FEED contracts for Train 7 to the B7 JV Consortium (KBR, TechnipFMC and JGC) and SCD JV Consortium (Saipem, Chiyoda and Daewoo) as part of a competitive “dual FEED” strategy. Both the consortiums will produce a basic design engineering package (BDEP) with EPC pricing.5

Source:

1. ‘U.S. Energy Information Administration – Nigeria’, Iber Global Website, 30 December 2013

2. ‘NLNG: Major Milestones’, NLNG Website

3. Publications ‘Facts and Figures on NLNG 2018’, NLNG Website

4. ‘Nigeria LNG to restart Train 5 in July’, LNG World News Website, 28 June 2018

5. ‘NLNG Train 7: Better late than never’, Nigerian Tribune Website, 29 August 2018

6. ‘Press Release – Project NLNG Train 7 in Nigeria’, Chiyoda Corporation Website, 13 July 2018

7. ‘Bonny Island’, Hydrocarbons Technology Website

8. ‘Nigeria agency to allow LNG exports after $475 mln loss’, Fox News Website, 12 July 2013

9. ‘Nigeria LNG Declares Force Majeure’, LNG World News, 8 October 2012

10. Jamieson A. et al ‘Nigeria LNG – Overcoming Technical and Commercial Challenges To Become One Of The World’s Major Exporters Of LNG’, 14th International Conference & Exhibition on Liquefied Natural Gas Doha, Qatar, 2004

11. Siemens, ‘Optimizing the LNG Value Chain’

12. ‘Success Story: Flange-to-Flange Solution – 7EA’, GE Power & Water | Power Generation Services Website, December 2013