In January 1992, based on the discovery of substantial non-associated gas fields, the Oman government signed an MoU with Royal Dutch Shell, for its first LNG plant. A shareholders’ agreement was signed by the Government of Oman, Royal Dutch Shell, Total S.A., Korea Gas Corporation, Partex, Mitsubishi, Mitsui and Itochu in June 1993, leading to the establishment of Oman Liquefied Natural Gas LLC (Oman LNG) in 1994. The coastal town of Qalhat, Sur, in the South Sharqiyah Governorate, approximately 200 km south-east of Muscat, was identified as the site to construct the Oman LNG (OLNG) plant.

The signing of a long-term Sale and Purchase Agreement (SPA) with Korea Gas Corporation for supply of 4.1 MMTPA for 25 years, prompted construction to be initiated in November 1996. 2 LNG trains of capacity 3.3 MMTPA were built on the 1.4 square kilometre site. A 360-kilometre, 48-inch pipeline carries feed gas from Central Oman Gas Field Complex, operated by Petroleum Development Oman (PDO). In October 1998, another 25-year SPA was signed with Osaka Gas, followed by a 20-year agreement with India’s Dabhol Power Company, effectively committing the capacity of the plant almost entirely.

The first train was ready in 1999 and in 2000, His Majesty Sultan Qaboos bin Said inaugurated the Oman LNG plant. Maiden cargo from OLNG was dispatched to South Korea in April 2001. The company produces and sells Liquefied Natural Gas (LNG) and its by-product, Natural Gas Liquids (NGLs). The success of the 2 trains triggered further expansion plans, with construction of a 3rd train, christened Qalhat LNG, starting in 2004. The 3rd train was inaugurated in March 2006 and in September 2013, all 3 trains were integrated into the Oman LNG banner, with a consolidated capacity of 10.4 MMTPA.

In 2010, within a year of shipping its 1000th cargo, Oman witnessed devastation on account of Cyclone Phet and operations at OLNG were shut down temporarily. In 2015, gas shortage on account of rising domestic demand, led to rescheduling of some of the plant’s exports.1 The plant had been running at 75-80% capacity for a decade. However, in 2017, BP-Oman’s large Khazzan gas project came online, boosting the production of all 3 LNG trains to full capacity for the first time.2

The plant has a staff of 606 personnel and boasts of 88% Omanisation. The company sponsors higher education of 12% of its staff as well as professional qualification of another 8% of the employees.3 When Cyclone Guno rampaged through Oman in 2007, the company shut down all its non-essential work and directed its employees to relief work. They also donated $13 million to the Sultan’s fund and encouraged their staff to pitch-in by matching a 5-fold amount on all staff contributions.

OLNG is committed to safety, social responsibility and concern for the environment. 1.5% of its net income post tax is spent on Social Investment Programs (SIPs), with over $330 million already dedicated to more than 4,000 SIP projects. The company’s CSR funds are utilized for community projects in the region, national projects across the country, as well as for a reserve fund to ensure future sustainability. A US$40 million referral hospital was constructed for the host community, in addition to funding various health initiatives covering gene testing, cancer treatment, specialists training and establishing dental clinics. On the education forefront, OLNG invests in Smart Classrooms and mobile IT laboratories for remote schools, as well as supports programs for skill development and vocational training in the area. In addition, OLNG funds various programs covering sustainable fishing, cultural development, preservation of local heritage and sports & recreational activities.4

The company prides that its plant delivers world-class performance in minimising environmental impact on air, water and soil quality. OLNG is the single largest sponsor of the Environmental Society of Oman (ESO), that works on protecting indigenous species as well as waste reduction, reuse and recycle programmes. Oman LNG is also a leading sponsor of the Turtle Research and Exhibition Centre at Ras Al Jinz.

OWNERSHIP (Equity %)

| Government of Oman | 46.84% |

| Oman LNG (Oman Govt 51%, Shell 30%, Mitsubishi 2.77%, Mitsui 2.77%, Korea LNG 5%, Total 5.54%, Partex 2%, Itochu 0.92%) | 36.80% |

| Union Fenosa Gas | 7.36% |

| Osaka Gas | 3.00% |

| Itochu Corporation | 3.00% |

| Mitsubishi Corporation | 3.00% |

General Data

| Estimated Capital Cost (USD) | 2.5B |

| Plant Type | Onshore |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2002 |

| FEED Contractor | Chiyoda Corporation Foster Wheeler |

| EPC Contractor | Chiyoda Corporation Foster Wheeler |

| No. of Trains / capacity | 1 Train / 3.7 MMTPA |

| Production Start Year | 2006 |

| Products | LNG, LPG, Condensate, Propane, Butane |

| Gas Type | Non-associated Gas (NAG) |

Technical Data

| Cooling Media | Seawater |

| Liquefaction Technology | APCI AP-C3MR™ |

| Refrigeration Train Details: | |

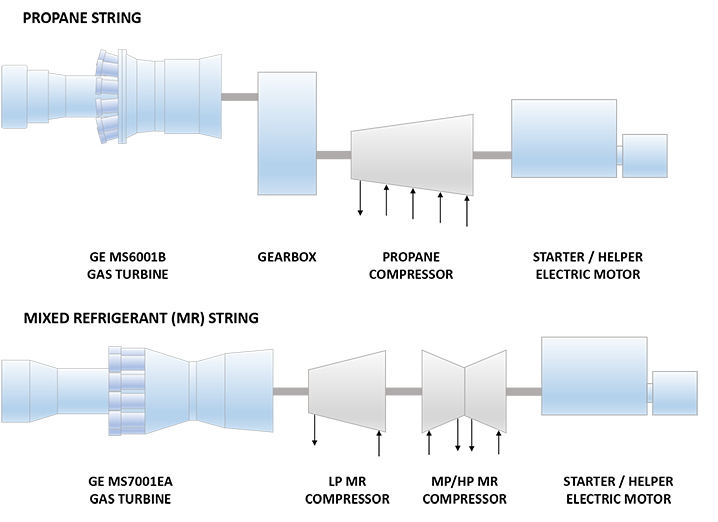

| Propane String | |

| Driver | GE PG6551B DLN1 (Frame 6B) Heavy Duty Gas Turbine |

| Gearbox | Double Helical Speed Reduction Gear box |

| Propane Compressor | 3MCL1004 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | 7.5 MW Synchronous Motor with Siemens VSD System |

| Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) MR Compressor | AN200 GE (Nuovo Pignone) Axial Compressor |

| Medium Pressure (MP) / High Pressure (HP) MR Compressor | 2BCL806 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | 7.5 MW Synchronous Motor with Siemens VSD System |

| Power Generation | 2 x GE PG6551B DLN1 (Frame 6B) Heavy Duty Gas Turbines |

Refrigeration Train Configuration

Key Facts

- The Qalhat LNG Train 3 has a capacity of 3.7 MMTPA, which is a debottlenecked version of Oman LNG’s 3.3 MMTPA Trains 1 & 2. The project shares Oman LNG’s two 120,000m3 storage tanks, jetty and berth. The plant has a lean gas package, feed gas line, air separation unit, a 1760 kW instrument air compressor, a new sea cooling water intake outfall and two 52 MVA Gas Turbine Generators.5

- QLNG was a fast-tracked project of 34 months. The insignificant 1 month start-up period from plant completion to first shipment was accomplished using Shell Global Solutions International BV’s Trademarked Flawless Start-up Initiative®. Lessons learned from the Oman LNG project were studied and same vendors were preferred. The project also accomplished 35% Omanisation ratio. 6

- The EPC contractor, Chiyoda-Foster Wheeler (CFW), achieved Ready For Start-Up (RFSU) in 33.43 months, 3 weeks ahead of schedule, with 20 million man-hours reported without any Loss Time Incident (LTI). LNG Production was achieved in a world record 9 days and 3 hours after RFSU and first cargo was shipped 30 days after RFSU.6,7

- Qalhat LNG has signed 14-20 years SPAs on FOB-basis (Free-on-Board) with Itochu Corporation, Mitsubishi Corporation and Osaka Gas of Japan, as well as Union Fenosa Gas of Spain.8

- In September 2018, Oman LNG began considering debottlenecking its 3 LNG trains, aiming to add 1.5 MMTPA to the facility’s current capacity of 10.4 MMTPA. An additional 0.5 MMTPA is expected by end of 2019 through few easy fixes, while major hardware upgrades could add another 1 MMTPA by 2021.9

- Oman LNG has received several awards and honours for sustainable growth in the LNG sector10,11

- An air quality analysis using Industrial Source Complex Short-Term (ISCST) dispersion model was conducted to predict the deterioration in air quality during construction and operation of QLNG Train 3.12

- A 200% increase in domestic gas demand led to availability of less than 25% of Oman’s gas production for LNG exports. To avoid breaching existing commitments, Oman LNG and Qalhat LNG were merged in April 2013. In a bid to increase LNG production by 20%, Qatari gas was imported through Abu Dhabi’s Dolphin Energy; an MoU was signed with Iran to build a pipeline linking IGAT (Gas trunkline); and BP was permitted to develop the unconventional gas reservoirs at Block 61 and the Khazzan and Makarem gas fields.13

- Oman LNG introduced specific measures to reduce flaring from its facilities. According to World Bank CO2 emission report 2015, Oman LNG reduced its flaring by 26% since 2005, with 1.9 billion cubic metres recorded in 2015 compared to 2.6 billion a decade ago. However, Oman still stands as the world’s 19th most flaring nation.14

Source:

1. Alarimi F. ‘Oman reschedules some gas exports as industry struggles’, Reuters Website, 3 September 2015

2. ‘BP Khazzan to plug shortfall in Oman LNG’s feed-gas needs’, Ministry of Information – Sultanate of Oman Website,16 July 2017

3. ‘Al Ghanjah – The Official Magazine of Oman LNG’, Oman LNG Website, May 2017

4. ‘Corporate Social Responsibility’, Oman LNG Website

5. ‘Eni LNG Brochure’, Eni Website, March 2016

6. Nakano M., van der Post A. ‘Qalhat LNG Project LNG’, Gastech 2005, Bilbao, Spain, March 2005

7. ‘Chiyoda’s Technological Expertise and Experience in Gas Value Chain’, Chiyoda Website, March 2017

8. ‘The LNG industry GIIGNL Annual Report 2018’, GIIGNL Website, 2018

9. ‘Debottlenecking to boost Oman LNG’s output’, Business Gateways International Website, 12 September 2018

10. ‘Oman LNG Development Foundation’, International Gas Union Website, , 30 March 2017

11. ‘Oman LNG Annual Report 2017’, Oman LNG Website, 2018

12. Abdul-wahab S. et al. ‘Environmental Impact Assessment for Oman LNG Expansion Project : NO2 Air Quality Analysis with a Proposal for a Third Train’, Toxicological & Environmental Chemistry Journal | Volume 83, 2002 – Issue #1-4, Taylor & Francis Online Website, 2002

13. Amirzadeh T. ‘Oman: A discrete future giant exporter of LNG’, 6 July 2014

14. Al-Quwaitai A., Krishnan P.K. ‘Study and Design of Flare Reduction Initiative in the Region: A Case Study of Gas Flaring Reduction at Oman Liquefied Natural Gas Company’, Journal Repository Website, 27 February 2016