Angola LNG has come a long way from its feasibility study agreement in 1997 to becoming one of the largest energy projects in the African Continent and the first LNG plant supplied with associated gas in the world. The ALNG project in Soyo (350 km north of Luanda), is also one of the largest single investments in the Angolan oil and gas industry. The project is a result of a partnership between Sonangol, Chevron, BP, ENI and Total.

Plant construction was initiated in 2008 and completed in 2012, enabling first production of LNG in 2013. In addition to supplying LNG, propane, butane and condensate worldwide, the project also supplies pressurized butane to the Angolan market to help meet local industrial and energy needs. Feed gas supply to the plant comes from offshore gas fields on blocks 14, 15, 17 and 18. The plant consumes around one billion cubic feet of gas a day and has a projected lifespan of 30 years.

The first cargo of LNG was shipped to Brazil in 2013. Long term charters of 7 LNG vessels (160,000 m3) deliver Angolan LNG worldwide, which at full capacity offers 70 LNG cargos annually. Of the 3 jetties at the plant, one is dedicated to LNG ships, the second to propane, butane and condensate and the third to pressurized butane loading.

ALNG has initiated various social investment projects in addition to promoting the use of local companies and providing training and local jobs during the construction and operation phases. Around $590 million has already been invested into its Community Investment programs.

OWNERSHIP (Equity %)

| Chevron Corporation | 36.40% |

| Sonangol | 22.80% |

| BP | 13.60% |

| TOTAL | 13.60% |

| Eni | 13.60% |

General Data

| Estimated Capital Cost (USD) | 10 B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2007 |

| FEED Contractor | Bechtel |

| EPC Contractor | Bechtel |

| No. of Trains / capacity | 1 Train / 5.2 MMTPA |

| Production Start Year | 2013 |

| Products | LNG, Propane, Butane, Condensate |

| Gas Type | Associated Gas |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | CoP Optimized Cascade® |

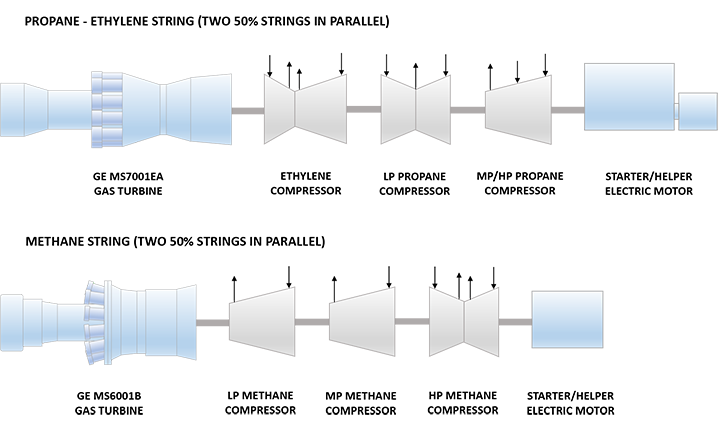

| Refrigeration Train Details: | |

| Propane – Ethylene Strings 1 & 2 | |

| Driver | GE MS7121EA DLN (Frame 7EA) Heavy Duty Gas Turbine |

| Ethylene Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| LP Propane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| MP/HP Propane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| Starter/Helper Motor | ABB 18MW Synchronous Motor |

| Methane Strings 1 & 2 | |

| Driver | GE PG6581B DLN (Frame 6B) Heavy Duty Gas Turbine |

| LP Methane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| MP Methane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| HP Methane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| Starter/Helper Motor | ABB 6.6 MW Induction Motor |

Refrigeration Train Configuration

Key Facts

- The Frame 7EA refrigeration trains at Angola LNG are the longest LNG refrigeration trains in the world. 1

- The Frame 7EA refrigeration trains are the only LNG trains in the world to have Propane and Ethylene services on the same shaft.2

- At the time of its construction, the only other similar nameplate capacity (5.2 MMTPA) LNG plant utilizing the ConocoPhillips Optimized Cascade® liquefaction technology was Atlantic LNG Train 4 which employed 8 refrigeration drivers (GE Frame 5Ds) compared to 4 drivers at Angola LNG.2

- Angola LNG is the world’s first LNG plant supplied exclusively with associated gas that is a byproduct of crude oil production from several offshore blocks.3

- In April 2014, the plant was shut down due to a major rupture on a flare line. No explosion, fire or injuries were caused as a result of the incident. The plant was restarted in May 2016.4

- The Congo river deposits an enormous amount of earth and sand necessitating annual dredging work at the plant.5

- Angola LNG has an active sea turtle management program which focuses on the physical safeguarding of sea turtles and their nests.6

- The original destination for the LNG from Angola LNG was a regasification terminal to be built near Pascagoula, Mississippi. During the course of the design and construction of the project, the world LNG landscape completely changed, and the US was no longer a market for LNG import.7

- The project is expected to generate $180 million through the sale of carbon credits. It will help reduce 13 million tons of carbon dioxide emissions.8

- Angola LNG conducted a Front-End Engineering and Design (FEED) competition between Bechtel Corporation and a joint consortium of Kellogg Brown & Root Inc., JGC Corporation, and Technip U.S.A which ended in Bechtel Corporation being awarded the EPC contract for the project in 2007.

Source:

1. https://compressortech2.com/latest-advances-lng-compressors

2. Application of Novel Compressor/Driver Configuration in the Optimized Cascade® Process (https://www.aiche.org/conferences/aiche-spring-meeting-and-global-congress-on-process-safety/2009/proceeding/paper/7a-application-novel-compressordriver-configuration-optimized-cascader-process)

3. https://www.chevron.com/projects/angola-lng

4. https://www.reuters.com/article/angola-lng/rpt-update-1-angola-lng-shutdown-to-last-until-mid-2015-idUSL6N0OE4C520140528

5. https://fairplay.ihs.com/dredging/article/4292091/dredging-angola-s-soyo-keeps-lng-moving

6. https://commdev.org/userfiles/chevron_angola_case_study.pdf

7. https://www.petroleumafrica.com/angola-lng-gets-final-investment-decision/

8. https://www.hydrocarbons-technology.com/projects/angola-lng