In 1971, natural gas was discovered in the North Field, which is spread over a 6000 square kilometre area off the northeast coast of Qatar. The importance of this monumental discovery took a long time to percolate into commercial gain. Multiple drilling appraisals over 15 years confirmed that the field was the largest non-associated natural gas field in the world, home to almost 10% of the world’s known reserves. Suddenly Qatar found itself as owner of the third largest gas reserves in the world, after Russia and Iran. The North Field Bravo off-shore complex (NFB) was commissioned in 1996 and the RasGas Alpha off-shore complex (RGA) was started in 1999. The off-shore operations now comprise of 209 wells, which supply 18.5 billion cubic feet of sour gas daily.

In the mid-1990s Qatar invested millions of dollars to develop the port facilities and associated infrastructure at Ras Laffan, to facilitate the exploration, storage and export of its massive natural gas resources. The location, 80 kms north-east of Doha, was in ideal proximity to the North Field, as well as advantageously positioned on international maritime routes to the Far East and Europe. The on-shore operations at Ras Laffan Industrial City are spread over 7.80 square kilometres. By 2005 the port had shipped over 1000 cargos and by 2015 this number rose rapidly to 5000.

The history of LNG in Qatar started with the establishment of Qatar Liquefied Gas Company Limited (Qatargas 1) in 1984. In 1996, Qatar received delivery of its first LNG Vessel – “Al-Zubara”. Initially the operations proceeded at a glacial pace, with eight years underway before the first Sale and Purchase Agreement (SPA) was signed and 12 years for delivery of first LNG cargo. However, by 2010, Qatar established itself as the largest producer of LNG in the world with a capacity to export 77 MMTPA of LNG.

By 2007 Qatargas 1 project was already successfully operating 3 trains since a decade, while the 2 mega trains, owned by Qatargas 2, were due to be inaugurated and construction of a 6th train, owned by Qatargas 3, was underway. In 2007, Qatar Liquefied Gas Company Limited 4 (Qatargas 4) was founded to construct the 7th train, with Qatar Petroleum (70%) and Royal Dutch Shell (30%) as shareholders. In 2008, Qatargas 4 tapped new buyers for Qatari LNG by signing long-term sales deals with China and Dubai. The project, which use Air Product’s proprietary APX process technology, added yet another 7.8 MMTPA capacity to Qatar’s gas exports, when it started production in 2011.

Qatargas 3 and 4 projects were developed and executed by a joint team and share various infrastructure, including 33 wells, 3 unmanned platforms, 2 subsea pipelines and 3 onshore injection wells for waste water disposal. Qatargas 4 plant produces LNG, LPG, high purity grade sulfur and condensate, consuming 1.4 billion standard cubic feet of gas per day. The project has chartered a fleet of 8 Korean-built Q-Flex and Q-Max ships, each with a capacity of approximately 210,000 to 266,000 cubic metres respectively.

In 2018, Qatargas and RasGas operations were merged into one global energy operator – Qatargas. Today the Ras Laffan Industrial City (RLIC) is home to a workforce of approximately 115,000 personnel. Qatargas is working towards Qatarization of its workforce and aims to accomplish over 50% Qatari workers by 2030. There is a strong focus on hiring, training and maintaining Qatari employees. Qatar Petroleum together with US University Texas A&M established, the Ras Laffan Emergency and Safety College for imparting training on industrial, hazardous materials, municipal, rescue and emergency medical services. In line with the goals of Qatar National Vision (QNV) 2030, Qatargas not only strives to exceed regulatory requirements, but also proactively works on initiatives for Green House Gas (GHG) management, sustainable waste management and waste reduction, wastewater management, air emission control and flare reduction. In 2015, the Jetty Boil-off Gas Recovery project (JBOG) was inaugurated in order to mitigate the flaring at Ras Laffan LNG loading berths by 90%.

OWNERSHIP (Equity %)

| Qatar Petroleum | 70.00% |

| Royal Dutch Shell | 30.00% |

General Data

| Estimated Capital Cost (USD) | 8 B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2005 |

| FEED Contractor | Chiyoda Corporation |

| EPC Contractor | Chiyoda Corporation Technip |

| No. of Trains / capacity | 1 Train / 7.8 MMTPA |

| Production Start Year | 2011 |

| Products | LNG, LPG, Condensate |

| Gas Type | Non-associated Gas (NAG) |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | APCI AP-X™ |

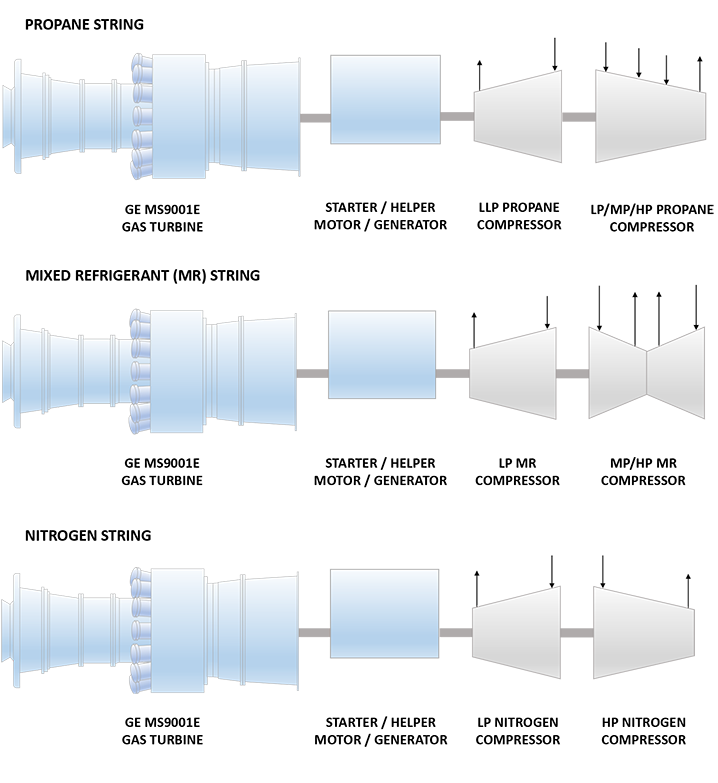

| Refrigeration Train Details: | |

| Propane String | |

| Driver | GE PG9171E DLN (Frame 9E) Heavy Duty Gas Turbine |

| Starter Helper Motor/Generator | ASI 45 MW Synchronous Motor / Generator |

| LLP Propane Compressor | MCL1402 GE (Nuovo Pignone) Centrifugal Compressor |

| LP/MP/HP Propane Compressor | 3MCL1403 GE (Nuovo Pignone) Centrifugal Compressor |

| Mixed Refrigerant String | |

| Driver | GE PG9171E DLN (Frame 9E) Heavy Duty Gas Turbine |

| Starter Helper Motor/Generator | ASI 45 MW Synchronous Motor / Generator |

| LP MR Compressor | MCL1805 GE (Nuovo Pignone) Centrifugal Compressor |

| MP/HP MR Compressor | 2BCL1006 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Nitrogen String | |

| Driver | GE PG9171E DLN (Frame 9E) Heavy Duty Gas Turbine |

| Starter Helper Motor/Generator | ASI 45 MW Synchronous Motor / Generator |

| LP Nitrogen Compressor | MCL1402 GE (Nuovo Pignone) Centrifugal Compressor |

| HP Nitrogen Compressor | BCL1003 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

Refrigeration Train Configuration

Key Facts

- Qatargas 4’s key customers are Centrica of United Kingdom; Marubeni of Japan; Petrochina of China; Petronas of Malaysia; and Uniper of Germany. These clients have signed long term SPAs of durations ranging between 12-25 years and LNG delivery agreements on a DES-basis (Delivered Ex Ship).1

- In 2017, Qatargas supplied LNG to 24 countries around the world. However, the country’s worldwide market share decreased to 19.7%, from 27.3% in 2016. Over half of India, Pakistan, Thailand and Singapore’s LNG imports in 2017 originated from Qatar.1

- On February 8, 2011, Qatargas became the world’s largest LNG producer with the start-up of Qatargas 4 Train 7, which has a production capacity of 7.8 MMTPA.2

- In August 2014, LNG from Qatargas 4 was used to commissioned China National Offshore Oil Corporation’s (CNOOC) new Hainan LNG terminal. The cargo was delivered on-board the Q-Max class LNG vessel ‘Rasheeda’.3

- On November 9, 2014, Qatargas successfully started its $1 Billion Jetty Boil-off Gas Recovery (JBOG) Project in Ras Laffan Industrial City. The JBOG project, touted as the biggest environmental project in the world, is designed to eliminate flaring by 90%. Annually, approximately 29 million cubic feet of natural gas, which was previously flared during LNG ship loading, is recovered and utilized in the LNG plants as feed or fuel. This is equivalent to saving 1.6 million tonnes of CO2 per year.4

- Over a period of five months, during the underwater pipeline laying activities for Qatargas 2, 3 and 4 projects, 4500 coral colonies were preserved by moving them to a more suitable area south-east of Al Khor. Qatargas conducts six monthly environmental monitoring surveys to determine the success of the relocation program and to establish a baseline for the monitoring the reef health and viability.5

- In 2014, Qatargas won first place in the ‘Large Size Enterprise’ category across the MENA region at the Arabia CSR Awards. It also became the first Qatari company to be awarded British Safety Council’s Sword of Honour and Globe of Honour for its HSE initiatives.5

Source:

1. ‘The LNG industry GIIGNL Annual Report 2018’, GIIGNL Website, 2018

2. ‘Qatar Petroleum Annual Report 2011’, Qatar Petroleum Website, 2011

3. ‘Qatargas delivers cargo to Hainan LNG terminal’, LNG World News Website, 18 August 2014

4. Alagos P. ‘Biggest environmental project in the world opens in Qatar’, Gulf Times Website, 29 April 2015

5. ‘Leaders in Safety, Health and Environmental Practices’, The Pioneer Magazine, 30thAnniversary Special Edition, 2015