Malaysia’s history as a major LNG producer began with the discovery of substantial gas reserves in Sarawak’s Central Luconia basin, 125 km from Bintulu, in the 1960s. On 31st March 1978, PETRONAS signed a joint venture agreement with Shell BV, Mitsubishi Corporation and Sarawak government to initiate the country’s first liquified natural gas projects. The small town of Bintulu in the island of Borneo, Malaysia was selected as an ideal site due to its strategic location and proper geographical condition for developing Sarawak’s first deep sea port, specifically to cater to large LNG ships that will call the port in the future. The Petronas LNG complex is built on an area covering over 276 hectares.

MLNG Satu, Malaysia’s first liquefaction plant, with 3 LNG processing trains of combined capacity 8.1 MMTPA, started its operation on November 1982. The success of the project and growing LNG demand in the world spurred Malaysia to quickly develop expansion plans for their LNG assets. On 1st June 1992, MLNG Dua was incorporated and the first shipment of cargo from the expansion project was dispatched on 19th May 1995. Further expansion necessitated incorporation of Malaysia LNG Tiga Sdn. Bhd. (MLNG Tiga), on 8th November 1995, as a joint venture company between PETRONAS (60%), Shell B.V. (15%), Sarawak government (10%), JX Nippon (10%) and Diamond Gas (5%). The third plant unlike its predecessors had only two processing ‘trains’ with an output of 6.8 MMTPA. One more LNG storage tank of capacity 120,000 cubic meter was also added. While MLNG Satu and Dua were developed in a somewhat integrated manner, with several shared utilities, MLNG Tiga was developed independent of the existing utilities. The plant shipped its first cargo on 19th March 2003.

On 12 July 2005, MLNG Tiga signed a Sales & Purchase Agreement (SPA) with Korea Gas Corporation (KOGAS) to supply LNG for 20 years from 2008. The SPA followed several spot cargoes sales in 1991, a long-term contract in 1993, and medium and short-term supply contracts in 2003 and 2004. On 31 July 2006, MLNG Tiga signed a SPA with Shanghai LNG Company Limited for supply of LNG for 25 years beginning 2008. This was incidentally PETRONAS’ first LNG deal with China. On 26 October 2009, MLNG Tiga delivered its first LNG cargo of 60,500 metric tonnes to Shanghai LNG Company Limited, at the Shanghai LNG Yangshan LNG Terminal. MLNG also has long term contracts with KOGAS of South Korea, and several Japanese customers including Tokyo Electric Power Co. Inc. and Tokyo Gas Co. Ltd., who renewed their 20-year sale and purchase agreement on 17 March 2003.

The plant uses Air Products & Chemicals Inc.’s (APCI) Propane Pre-cooled Mixed Refrigerant (C3-MR) liquefaction concept and has maintained a 100% success delivery rate to its customers, establishing a reputation as a preferred and reliable LNG supplier in the world. At one point of time the PETRONAS LNG complex became the world’s largest LNG processing facility in a single location, until Qatar established itself as an international LNG giant. The plant exports Liquefied Natural Gas (LNG), Propane and Butane (LPG) and Stabilized Gasoline.

MLNG is actively involved with various education, capability-building and outreach programmes. The initiatives cover a wide range of human development needs to improve the lives and well-being of both present and future generations. Dedicated skills development and industrial training programs have been initiated for nurturing its workforce as well as providing valuable exposure to students from the community. The company claims that sustainability is an integral part of how they operate, as they conduct their business in an ethically, socially, and environmentally responsible manner. Biodiversity, Environmental and Conservation (Beacon) Project at Similajau National Park (SNP) is a collaborative venture with Sarawak Forestry for the preservation and conservation of marine biodiversity in Bintulu waters through programs such as Friends of Nature. MLNG deployed approximately 1,500 artificial reef balls at the Similajau National Park, at a cost of RM4.6 million, to improve the livelihood of the local community and biodiversity conservation.

OWNERSHIP (Equity %)

| PETRONAS | 60.00% |

| Sarawak State Government | 25.00% |

| JX Nippon Oil & Energy | 10.00% |

| Diamond Gas (80% Mitsubishi Corporation, 20% JAPEX) | 5.00% |

General Data

| Estimated Capital Cost (USD) | NA |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 1995 |

| FEED Contractor | Shell Internationale Petroleum Maatschappij (SIPM) |

| EPC Contractor | JGC Corporation KBR Sime Engineering Sdn Bhd |

| No. of Trains / capacity | 2 Trains / 3.85 MMTPA each |

| Production Start Year | 2003 |

| Products | Liquefied Natural Gas (LNG), Propane and Butane (LPG) and Gasolene |

| Gas Type | Non-associated Gas (NAG) |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | APCI AP-C3MR™ |

| Refrigeration Train Details: | |

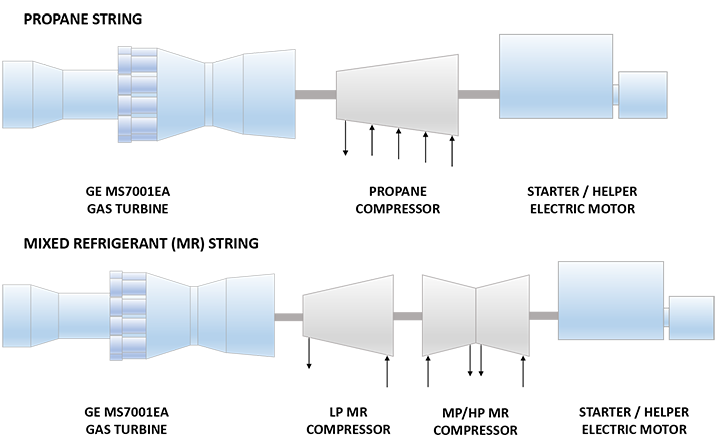

| Propane String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | 3MCL1405 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | 10 MW Siemens Synchronous Motor with VSD System |

| Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) MR Compressor | AN200 GE (Nuovo Pignone) Axial Compressor |

| Medium Pressure (MP) / High Pressure (HP) MR Compressor | 2BCL806 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | 10 MW Siemens Synchronous Motor with VSD System |

| Power Generation | 4 x GE MS5001 DLN1 Heavy Duty Gas Turbines |

Refrigeration Train Configuration

Key Facts

- MLNG Tiga was incorporated after discovery of additional gas fields near Sadawak. The main gas supply source for the project was from the Jintan and Helang gas fields. The gas is fed to the plant via a new gas gathering system.1,2

- MLNG Tiga effectively utilized the learning from MLNG Satu and Dua to enhance its design, efficiency and capacity. The Propane Precooled Mixed Refrigerant (MR) liquefaction process employs fully air-cooled GE Frame 7EA gas turbines for the propane and MR compressor trains. Endflash and liquid expander systems contribute to maximizing production capacity, while fuel efficiency is enhanced using the waste heat from the gas turbine exhaust. The four stage propane precooling compressor at MLNG Tiga uses Frame 7 rather than the Frame 6 gas turbines used at MLNG Dua. The gas turbines are equipped with electrical variable speed starter motors. The MR starter motor can double up as helper motor during normal operation while the propane starter motor is capable of generating electricity.2

- MLNG Tiga is the first LNG project to engage fully air cooled, large, single speed gas turbine drivers. As a result of not constructing another seawater cooling system, the impact on existing plants is mitigated, capital expenditure is efficiently spread out and a modular approach for adding a third train in the future is realised. By using a double air cooler bank in parallel over the full length of the train, as well as reduction of equipment items, 150% of MLNG Dua’s capacity is constructed on a similar plot size.2

- MLNG Tiga is also equipped with additional facilities to make it fully independent. These include, an LNG storage tank of 120,000m3, a condensate tank, a dual-loading jetty, a slug catcher with gas metering and liquid stabilization facilities.2

- MLNG Tiga achieved full operation in 2003, making the PETRONAS LNG Complex in Bintulu the world’s largest LNG producing single location, with 23 million tonnes per annum capacity. Subsequently Qatar ousted MLNG by constructing multiple Mega Trains.3

- MLNG Tiga was originally owned by PETRONAS (60%), Shell (15%), Sarawak Govt. (10%), JX Nippon (10%) and Diamond Gas (5%). Following the expiry of the MLNG Satu and Dua joint venture agreements in 2003, MLNG Tiga became Shell’s lone interest in the Petronas LNG complex. However, in June 2018, Shell sold its equity to Sarawak State Financial Secretary (SFS) for USD 750 million, increasing SFS’s equity to 25%.4,5

- MLNG Tiga dispatched its maiden cargo on 19 March 2003 to Japan Petroleum Exploration Co. Ltd. (JAPEX).6

- The major customers of MLNG Tiga include JAPEX, Hiroshima Gas, Tohoku Electric, Osaka Gas, Toho Gas, Tokyo Gas from Japan; KOGAS from South Korea; and Shanghai LNG of China.7

- Unlike other LNG projects of the region, MLNG Tiga commenced production with relatively fewer long term sales contracts in place. However, the risk paid off once the plant came online in 2003, as LNG supply fell short of International demand and MLNG Tiga was able to secure additional contracts.8

- MLNG Satu and Dua share several utilities, while MLNG Tiga has its own independent utilities. However, the 3 plants are integrated and use common LNG rundown and storage facilities, ensuring back-up for each other, if required.9

- The propane compressor employed at MLNG Tiga is about twice the size of that at MLNG Satu. In addition, the number of compression stages are also increased from 3 to 4, thereby increasing the cycle efficiency. MLNG Dua and Tiga use axial LP MR compressors to account for the increased MR flows. The size of these MR compressors is also significantly larger than that used at MLNG Satu10

- A 3-bundle design was used for the cryogenic exchanger at MLNG Satu. The design was replaced with a 2-bundle version at MLNG Dua. However, this made the plant susceptible to operational upsets and tube leakages and necessitated stringent adherence to operation guidelines. Eventually, the 3-bundle design was re-employed in MLNG Tiga.10

- MLNG Tiga has a unique power exchange concept, wherein a synchronous electric motors/generators transfers excess power from the propane compressor to the MR compressor. In addition, a Load Commutated Inverter is installed to transfer excess power to and from the plant electrical distribution system, as required.11

- On 16th August 2003, barely a few months after Train 7 came online, a fire broke in the Waste Heat Recovery Unit (WHRU), following a trip in the Propane gas turbine at MLNG Tiga. An investigation of the incident revealed the exact cause of the incident. An improved welding design for the regeneration coil, as well as a new safeguarding system were recommended. These recommendations were immediately also applied to the under construction Train 8, which subsequently began operation in November 2003. Train 8 fulfilled the contracted LNG volumes for the plant until March 2004, when Train 7 resumed operation.12

- Around 2005, MLNG Tiga generated close to 5200t/d of acid gas. To meet the ever stringent environmental regulations, MLNG built the world’s largest acid gas incinerator. The mammoth design and process control challenges were ultimately addressed by employing horizontal fired burners with tangential arrangement at the incinerator wall.13

Source:

1. ‘Milestones – Our History’, MLNG Website

2. Ismail N.H., Grootjans H. ‘The MLNG Tiga Project’, 12th International Conference & Exhibition on Liquefied Natural Gas (LNG 12), Perth, Australia, May 1998

3. ‘Petronas Annual Report 2004’, MLNG Malaysia Website, 2 April 2005

4. ‘Our Companies – Corporate Information’, MLNG Website

5. ‘Shell completes Malaysia LNG Tiga equity sale’, Shell Global Website, 20 June 2018

6. ‘Our Facilities – Our Operations’, MLNG Website

7. Shepherd R. et al. ‘Potential LNG Production From North Slope Gas | Report for The State of Alaska by Gas Strategies’, ARLIS Website, 12 May 2008

8. Ball A. et al. ‘The Asia Pacific LNG Market – Issues and Outlook: ABARE Research Report’, Nautilus Website, November 2004

9. Huai P.K. ‘MLNG Rejuvenation and MLNG / MLNG Dua Revamp (MRR) Project: Successes, Challenges and Lessons Learnt’, 14th International Conference & Exhibition on Liquefied Natural Gas (LNG 14), Doha, Qatar, March 2004

10. Kasmuni A.A. et al. ‘The Malaysia LNG Complex—Sustainable Growth’, 13thInternational Conference & Exhibition on Liquefied Natural Gas, Seoul, Korea, May 2001

11. Ismail E.N.H. et al. ‘Application of Dynamic Simulation for Design and Commissioning of LNG Plants (Experience in MLNG Tiga Project)’, 14th International Conference & Exhibition on Liquefied Natural Gas (LNG 14), Doha, Qatar, March 2004

12. Ismail E.N.H., Stuart T.R. ‘Train 7 Fire Incident at the PETRONAS LNG Complex, Bintulu, Malaysia’, GasTech 2005, Bilbao, Spain, March 2005

13. Saad J. et al. ‘World Largest Tangentially Fired Acid Gas Incinerator in LNG Plant: Startup and Operational Experiences’, 23rd World Gas Conference 2006, Amsterdam, Netherlands, June 2006