Yemen is strategically located along key maritime routes, which allows the country ease of accessibility to markets in Asia-Pacific as well as Europe and trans-Atlantic. The history of Oil & Gas production in Yemen began in 1986. In 1995 a survey was initiated to identify the most appropriate site for constructing Yemen’s first LNG plant, however the initiative was stalled in 1997 amidst the Asian economic crisis. The project was finally launched in August 2005, upon signing long term sales and purchase agreements with 3 of the 5 largest LNG importers of the world; Korea Gas Corporation (KOGAS), GDF-Suez, and Total Gas & Power Ltd.

The plant, located at Balhaf 200 km SW of Mukalla, became Yemen’s largest ever industrial investment, with a budget of US$ 4.5 billion. The LNG chain includes a 25 km – 20-inch transfer line linking the 2 gas processing units at Marib, a 320 km – 38-inch main pipeline carrying gas to the plant at Balhaf and a spur line transporting domestic gas to central Yemen.

During the construction phase, in excess of 12,000 jobs were created. In addition, a dedicated skills development program was initiated, to train Yemeni operators, who would operate the plant for its 25-year projected life span. Right from the start Yemen LNG has conducted public consultation and disclosure programs, to seek opinion and approval of the community through key stakeholders. Specific provisions were put into place for safe access to drinking water in the districts through which the pipeline route crosses, for avoiding physical resettlement of local people, and for the benefit of the local fishermen to offset any loss in their livelihood.

First LNG export cargo from the 6.7 MMTPA plant was shipped on 7 November 2009. The gas reserves were proven sufficient for plant operations for another 20 years. However, local unrest in the region witnessed air strikes and ground fighting, which forced shutdown of all LNG production and export on 14 April 2015. As of August 2018, the plant is still in shut-down mode.1

Yemen LNG has contributed to building, refurbishment and upgradation of facilities at a number of schools in the area. The plant has provisions to supply electricity to the adjoining town through diesel generating units which were reinforced with solar electricity in 2011. Many programs have been initiated by Yemen LNG to improve agriculture, animal health, capacity building of women and medical infrastructure in the area.2 The plant has programs in place for air quality monitoring, Wastewater and Water Resource Management, Local Community Waste Management and biodiversity preservation.3

OWNERSHIP (Equity %)

| Total S.A. | 39.62% |

| Yemen Gas Company | 16.73% |

| Hunt Oil Company | 17.22% |

| SK Corporation | 9.55% |

| KOGAS | 6.00% |

| Hyundai Corporation | 5.88% |

| General Authority for Social Security & Pensions of Yemen | 5.00% |

General Data

| Estimated Capital Cost (USD) | 2.25B per Train |

| Plant Type | Onshore Stick-built |

| Plant Stage | Not Operating |

| Final Investment Decision (FID) Year | 2005 |

| FEED Contractor | Technip |

| EPC Contractor | Technip JGC Corporation Kellogg Brown & Root (KBR) |

| No. of Trains / capacity | 2 Trains / 3.6 MMTPA each |

| Production Start Year | 2009 (Train 1) 2010 (Train 2) |

| Products | LNG |

| Gas Type | Non-associated Gas (NAG) |

Technical Data

| Cooling Media | Seawater |

| Liquefaction Technology | APCI AP-C3MR/SplitMR® |

| Refrigeration Train Details: | |

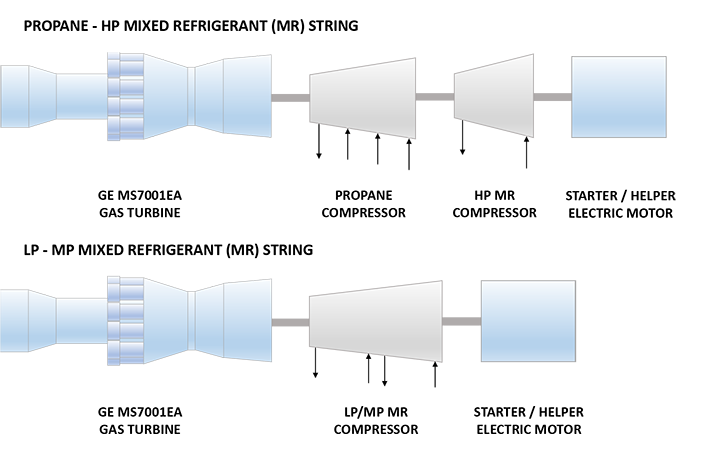

| Propane – HP Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | 88M6-4 Elliott Horizontally Split Centrifugal Compressor |

| High Pressure (HP) MR Compressor | 60M5 Elliott Radially Split Centrifugal Compressor |

| Starter/Helper | Converteam 12 MW Induction Motor with Voltage Source Inverted (VSI) Drive |

| LP – MP Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) / Medium Pressure (MP) MR Compressor | 88M6I Elliott Horizontally Split Centrifugal Compressor |

| Starter/Helper | Converteam 12 MW Induction Motor with Voltage Source Inverted (VSI) Drive |

| Power Generation | Qty: 3 GE PG6581B (Frame 6B) Heavy Duty Gas Turbines |

Refrigeration Train Configuration

Key Facts

- Yemen LNG is the first LNG plant in Yemen, the Arab world’s poorest state, and is its largest industrial project.4

- Yemen LNG is the first LNG plant to utilize induction motors with voltage source inverted (VSI) drives as starter/helper motors for the refrigeration compressor strings. Previous plants had utilized either synchronous motors or steam turbines.5

- At YLNG, the gas emitted from the LNG tanks is used to produce electricity for the plant on-site. This is now the only power source available in a region where there are no other remaining electricity production and distribution grids.6

- On 4th April 2015, as a result of growing conflict in Yemen and security concerns at the facility, production was stopped at Yemen LNG. A reduced team of 50 volunteer employees were left to operate the plant utilities and ensure equipment was maintained during the downtime. After several months without production, the plant was in desperate need to make up LNG levels in the LNG tanks and ethane inventory in the refrigerant loops. Importing LNG or Ethane was not an option in the unstable political climate. Taking inspiration from Woodside Energy’s experience at Pluto LNG, personnel at Yemen LNG designed a new operating system for producing ethane onsite using a ‘once through MR process’. This was a first for the APCI process. The trains were restarted in October 2015 and following the newly created procedures, the plant was successfully able to replenish LNG and Ethane inventories and was shut down within a few weeks with levels restored.6

- Yemen LNG has a history of unexpected delays and security threats for instance in 2009 there were nearly 90 pirate attacks in the Gulf of Aden, of which about a third were on oil and gas tankers. In response, in July 2009 YLNG had to take help of naval vessels to escort its gas exports, and Yemen’s government said that it planned to set up new radar stations and an anti-piracy center with other countries in the region.7

- As part of its Marine Biodiversity Preservation, Yemen LNG hired international marine biologists for coral transplantation where more than fifteen hundred colonies were moved to safer locations and into suitable adjacent areas creating new natural habitats for the benefit of the local fish population. The transplantation program has been very successful with a coral survival rate of over 80 percent. The largest coral moved weighed 4 tonnes, a world record for moving a living coral.9

Source:

1. http://www.petroleum-economist.com/articles/politics-economics/middle-east/2018/omv-provides-faint-light-in-yemen-gloom

2. http://www.yemenlng.com/ws/en/go.aspx?c=soc_community

3. http://www.yemenlng.com/ws/en/go.aspx?c=soc_Environment

4. https://uk.reuters.com/article/lng-yemen-total-idUKL959162220091015)

5. Lecuyer P., Martinot B. ‘Yemen LNG – starter/helper application of VSI + induction motors for 4 LNG compressor lines (2 LNG trains)’

6. https://www.ep.total.com/en/innovations/best-innovators/best-innovators-2016/yemen-lng-teams-successfully-produce-ethane-despite

7. https://www.hydrocarbons-technology.com/projects/yemen-lng/

8. THE YEMEN LNG PROJECT, http://www.ivt.ntnu.no/ept/fag/tep4215/innhold/LNG%20Conferences/1998/Papers/4-4-Azalbert.PDF

9. http://www.yemenlng.com/ws/en/go.aspx?c=soc_env_corals