Cameron LNG is named after the Cameron Parish, which is famous for its lakes, wildlife and natural beauty. The plant is located 18 miles north of the Gulf of Mexico near the town of Hackberry in SW Louisiana, surrounded by marshy swamplands. The Cameron LNG regasification terminal was planned on a 260-acre industrial zoned site. Construction began in August 2005 and first commercial operations started in July 2009. In 2010, the liquefaction concept was developed in order to offer bi-directional (export/import) capabilities. In 2011, Cameron LNG proposed adding a liquefaction facility to its existing terminal. Construction was initiated in 2014 after FERC approved the liquefaction-export project.

At an estimated total investment of US$ 10 Billion, the liquefaction project is expected to have a nameplate capacity of 4.5 MMTPA across each of its 3 trains. Cameron LNG has received approval from the U.S. Department of Energy (DOE) to export up to 14.95 MMTPA, of domestically produced LNG. The Cameron expansion project offers an increase of LNG production by 9.97 MMTPA. The project has already signed 20-year supply agreements for its liquefaction capacity with GDF SUEZ S.A. and affiliates of Mitsubishi Corporation and Mitsui & Co., Ltd. Commercial operations are expected to commence in 2019.1

During the construction phase the project is expected to create approximately 6500 jobs. In the operation phase 160 full-time jobs will be created at the facility, whereas 60 full-time jobs will be created at Cameron LNG’s headquarters in Houston. The expansion project will add another 50 full-time jobs. Since 2003, Cameron LNG has donated more than US$ 2.5 Million to the region and have supported several programs for health and safety, environment, education and economic development.2

Over 500 acres of tidal marsh and emergent wetlands have been created in the area by constructively using dredge spoil material. An estimated 13,000 acres of viable wetlands are expected to be created during the life of the plant on account of periodic maintenance dredging. In addition, Cameron LNG has donated $100,000 to wetland restoration projects and contribute regularly to the Cameron Parish Rockefeller Wildlife Center.3

OWNERSHIP (Equity %)

| Sempra LNG & Midstream | 50.20% |

| Mitsui & Co. | 16.60% |

| Mitsubishi Corporation | 8.30% |

| Total | 16.60% |

| NYK Line | 8.30% |

General Data

| Estimated Capital Cost (USD) | 3.33B Per Train |

| Plant Type | Onshore Stick-built |

| Plant Stage | Under construction |

| Final Investment Decision (FID) Year | 2014 |

| FEED Contractor | Foster Wheeler |

| EPC Contractor | McDermott (CB&I) Chiyoda Corporation |

| No. of Trains / capacity | 3 Trains / 4.5 MMTPA each |

| Production Start Year | 2019 |

| Products | LNG |

| Gas Type | Shale |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | APCI AP-C3MR/SplitMR® |

| Refrigeration Train Details: | |

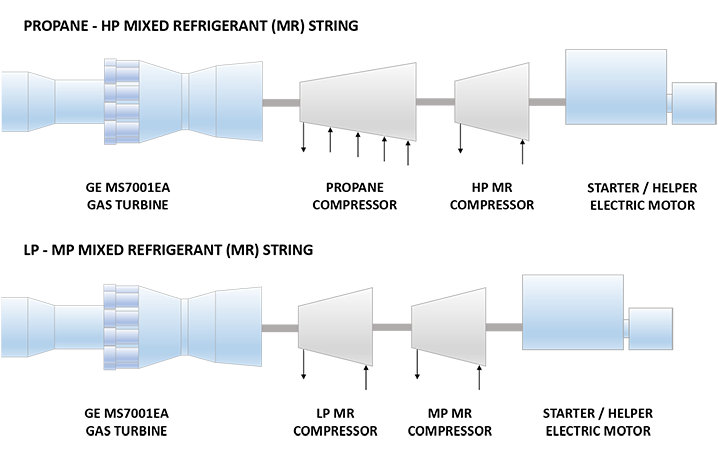

| Propane – HP Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| High Pressure (HP) MR Compressor | GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | Electric Motor with variable speed drive system (VSDS) |

| LP – MP Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) Compressor | GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Medium Pressure (MP) MR Compressor | GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | Electric Motor with variable speed drive system (VSDS) |

Refrigeration Train Configuration

Key Facts

- Construction of the liquefaction facilities will result in the creation of beneficial marsh wetlands in Cameron Parish.1

- FERC order to Cameron LNG’s export facility was challenged by environmental groups with regards to the effects of increased gas production and air pollution that could be induced by the project and the project’s effect on wetlands.4

- In December 2017, Sempra LNG & Midstream announced that it had reached a settlement agreement with its contractor, CCJV, related to the construction of Cameron LNG. The settlement resolved all of CCJV’s known and unknown claims to that date, including claims related to Hurricane Harvey.5

- In July 2018, Total closed its acquisition of Engie’s portfolio of LNG assets including Engie’s 16.6% stake in the Cameron LNG project. With this acquisition, Total become the 2nd largest global LNG player among the International oil companies.6

- Chicago Bridge & Iron Co. (CB&I), the prime contractor of the EPC consortium building Cameron LNG was acquired by McDermott International Inc. in May 2018. CB&I’s stock had collapsed in summer 2017, with the company announcing a USD 548 million write-down in August 2017 due to cost overruns on several projects.7

Source:

1. http://cameronlng.com/pdf/11337%20CameronFctShts_LiquefactionProject.pdf

2. http://cameronlng.com/giving%20back.html

3. http://cameronlng.com/environment.html

4. https://www.lnglawblog.com/2014/07/environmental-groups-challenge-cameron-lng-ferc-order-cameron-lng-says-too-late/

5. https://www.sempra.com/newsroom/press-releases/sempra-lng-midstream-announces-settlement-agreement-between-cameron-lng-and

6. https://www.total.com/en/media/news/press-releases/total-closes-acquisition-engies-upstream-lng-business-and-becomes-world-2-lng-player

7. https://www.bloomberg.com/gadfly/articles/2017-12-19/mcdermott-cb-i-deal-cheap-for-a-reason