The history of Cove Point LNG located near Lusby, Maryland, United States, on the western shore of the Chesapeake Bay, dates back to 1972, when the project was certified to import LNG and regasify it for domestic use. Between 1978-1980 the facility received gas from Algeria, however a sharp increase in gas price rendered the plant out of service. In 1994 the plant was transformed into a liquefaction and storage facility, but in 2003 imports were resumed. Over the years, storage capacity has been expanded from 7.8 billion cubic feet to the current 14.6 billion cubic feet. Dominion took over the operatorship of the terminal in 2002. Dominion Energy is one of the largest producers and transporters of energy in the US and operates one of the nation’s largest natural gas storage systems with approximately one trillion cubic feet of storage capacity.1

In 2013 Dominion applied for expansion and construction of an LNG Export facility.2 The expansion planned for an LNG production and export capacity of up to 5.75 million metric tons per year of natural gas and included a new 130 MW combined cycle generating station.3 Costing approximately $4.1 billion, it is the largest construction project ever for Maryland and for Dominion Energy.1

Cove Point LNG is a bi-directional facility, offering both import and export capabilities. Gas is sourced from the Marcellus Shale.5 After a series of delays, Dominion Energy shipped out its first LNG cargo in March 2018, becoming the 2nd US LNG export terminal in operation. The Project already has long-term contracts with Gail India and a joint venture involving Japan’s Sumitomo and Tokyo Gas.6

Dominion created about 3,600 jobs in the construction phase of Cove Point LNG.7 The project is touted to be the first facility of its kind in the United States to use waste heat to generate its electricity and wastewater from the new facility is recycled.8 Cove Point LNG operates in partnership with the Sierra Club, the Nature Conservancy, the Maryland Conservation Council and the Maryland Environmental Trust. Together they have built a stone abutment in front of the beach, filled it with the dredge material, and then planted native species in the brackish water marsh they created. This brackish marsh now protects the beach, along with the freshwater marsh behind that. Cove Point also claims to have planted about 750,000 plants in that marsh, and it’s been virtually all done with grade school and high school students and in partnership with the National Aquarium of Baltimore.9

OWNERSHIP (Equity %)

| Dominion Energy | 100% |

General Data

| Estimated Capital Cost (USD) | 4B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2013 |

| FEED Contractor | IHI E&C International Corporation Kiewit Corporation |

| EPC Contractor | IHI E&C International Corporation Kiewit Corporation |

| No. of Trains / capacity | 1 Train / 5.25 MMTPA |

| Production Start Year | 2018 |

| Products | LNG, Condensate |

| Gas Type | Shale |

Technical Data

| Cooling Media | Air |

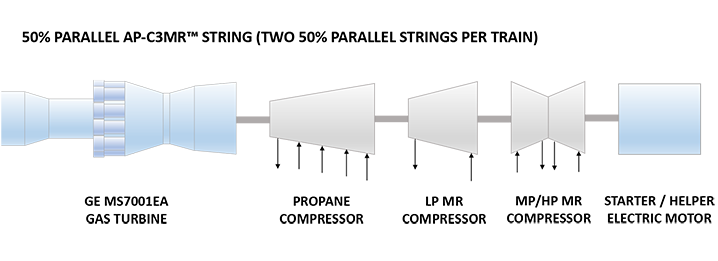

| Liquefaction Technology | APCI 50% Parallel AP-C3MR™ |

| Refrigeration Train Details: | |

| 50% Parallel AP-C3MR™ Strings 1 & 2 | |

| Driver | GE MS7121EA DLN (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | 3MCL1405 GE (Nuovo Pignone) Centrifugal Compressor |

| LP MR Compressor | MCL1405 GE (Nuovo Pignone) Centrifugal Compressor |

| MP/HP MR Compressor | 2BCL806 GE (Nuovo Pignone) Centrifugal Compressor |

| Starter/Helper Motor | GE Power (Converteam) 20MW Induction Motor |

Refrigeration Train Configuration

Key Facts

- Cove Point LNG became only the second LNG plant after Yamal LNG to use APCI’s 50% Parallel AP-C3MRTM liquefaction process. As opposed to the traditional AP-C3MRTM and AP-C3MR SplitMRTM processes, the 50% Parallel AP-C3MRTM configuration is composed of two identical refrigeration strings that allow LNG production at 50% rates when one gas turbine is not operating.

- Cove Point has built an underwater tunnel that is 1.25 miles long, to connect the onshore facilities to the offshore platform in the bay. The tunnel has three compartments; two compartments house the transfer piping that runs from onshore to offshore, and the middle compartment is for personnel transit, where workers typically transit by riding bicycles9.

- Dominion’s Cove Point LNG is the first LNG Terminal on the US East Coast capable of liquefying and exporting LNG10.

- In October 2015, about 5,000 gallons of a 50% solution of automotive antifreeze reportedly spilled from a pressure relief valve on an industrial heating system at the LNG terminal. The antifreeze is used in a system that processes LNG into natural gas by heating it. Dominion reported no injuries from the incident and no antifreeze was released from the Cove Point LNG site11.

Source:

1. https://www.maritime-executive.com/article/dominion-celebrates-cove-point-lng-operation

2. https://www.dominionenergy.com/about-us/moving-energy/dominion-energy-transmission-inc/facilities-projects-and-programs/cove-point/cove-point-terminal

3. http://dnr.maryland.gov/pprp/Documents/Dominion_Energy_Cove_Point_Fact_Sheet.pdf

4.https://mde.maryland.gov/programs/Permits/AirManagementPermits/Test/Dominion%20Cove%20Point%20LNG%20LP.pdf

5. http://www.naturalgasintel.com/articles/113012-report-says-dominion-cove-point-lng-facility-delayed-until-march

6. https://www.forbes.com/sites/judeclemente/2018/03/06/cove-point-becomes-2nd-u-s-liquefied-natural-gas-export-terminal/#4922054773e7

7. https://www.co.cal.md.us/Archive/ViewFile/Item/1155

8. https://www.co.cal.md.us/DocumentCenter/View/4680

9. http://www.gasprocessingnews.com/columns/201412/executive-qa-viewpoint.aspx

10. https://www.gepowerconversion.com/press-releases/ge-reaches-significant-project-milestone-dominion-cove-point-liquefaction-project-1-1

11. https://www.dcmediagroup.us/2016/10/26/local-police-set-alcohol-drug-checkpoint-cove-point-lng-construction-workers/