Gorgon LNG is flaunted as one of the largest LNG projects in the world and the largest single resource project of Australia. The Gorgon gas field was discovered way back in 1980, however Final Investment Decision (FID) on the project was reached only in September 2009. The proposed LNG plant would be constructed at Barrow Island, about 60 kilometres north-west of Western Australia. The infrastructure includes 3 processing trains, a domestic gas plant and 2 mammoth LNG tanks – capable of holding 180,000 cubic metres of LNG each. The project also includes one of the largest subsea installations in the world, which uses more than 250,000 tons of steel pipes.

In 2010, Sales and Purchase Agreements (SPA) were signed with KOGAS and Kyushu Electric of Japan, committing sale of LNG from the 3 proposed LNG trains. The plant’s first module was delivered in 2012, while the last of the 51 modules reached the site in January 2016. The plant is supplied with feed gas from the Gorgon and Jansz-Io gas fields. In the beginning of 2015, commissioning gas was introduced into the plant, leading to first production of LNG from train 1 on March 7, 2016. The first cargo was dispatched to JERA, onboard Chevron’s new state-of-the-art LNG carrier “Asia Excellence”, on March 20, 2016.

Train 2 started production on October 25, 2016, while train 3 achieved first LNG on March 28, 2017. Domestic gas supply was initiated on December 9, 2016. The plant, with a projected lifespan of 40 years, can produce 15.6 MMTPA of LNG, in addition to 20,000 barrels of condensate per day and can supply domestic gas equivalent to generating electricity for 2.5 million households. Gorgon has secured SPAs with several premier LNG buyers, including SK LNG Trading (4.15 MMTPA), Osaka Gas (1.375 MMTPA), Tokyo Gas (1.1 MMTPA), JERA (1.44 MMTPA), Kyushu Electric (0.3 MMTPA), JX Nippon Oil and Energy (0.3 MMTPA) and GS Caltex of South Korea (0.25 MMTPA).

Chevron Australia claims to have spent in excess of AU$1 billion on research and development projects in Australia since 2009. The Gorgon project has spent over AU$34 billion on local goods and services, contracting more than 700 Australian companies. More than 60,000 local jobs were created, including over 10,000 workers employed directly by the project. Chevron believes that their business succeeds best when the people they work with and the communities in which they operate succeed too. Accordingly, over 250 Chevron employees have clocked more than 3000 volunteer hours in Australia. Chevron supports over 35 community and not-for-profit projects, covering various issues including health, skill development, training and education.

Chevron also asserts to be committed to continually improving their environmental performance and reducing the potential impacts of their operations. The Chevron’s Barrow Island Quarantine Management System (QMS) is touted as the world’s largest non-government quarantine initiative and a model for environmental stewardship. 24 peculiar species and subspecies, which are found nowhere else on Earth, find a home on Barrow Island. The Gorgon LNG plant also showcases an industry-leading Carbon Dioxide injection system, which mitigates the venting of the greenhouse gas into the atmosphere.

OWNERSHIP (Equity %)

| Chevron Australia | 47.33% |

| Shell | 25.00% |

| ExxonMobil | 25.00% |

| Osaka Gas | 1.25% |

| Tokyo Gas | 1.00% |

| JERA | 0.42% |

General Data

| Estimated Capital Cost (USD) | 18 B Per Train |

| Plant Type | Onshore Modular |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2009 |

| FEED Contractor | KBR |

| EPC Contractor | KBR |

| No. of Trains / capacity | 3 Trains / 5.2 MMTPA each |

| Production Start Year | 2016 (Train 1) 2016 (Train 2) 2017 (Train 3) |

| Products | LNG, Condensate |

| Gas Type | Non-associated Gas (NAG) |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | APCI AP-C3MR/SplitMR® |

| Refrigeration Train Details: | |

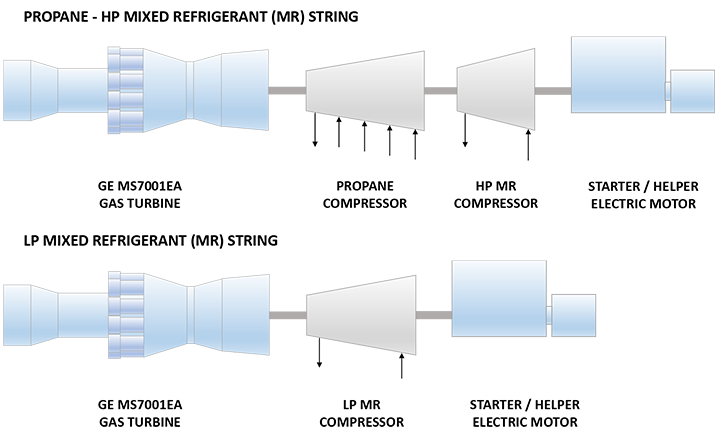

| Propane – High Pressure (HP) Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Propane Compressor | 3MCL1404 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| HP MR Compressor | BCL804 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | Siemens 24 MW Synchronous Motor with VSD System |

| Low Pressure (LP) Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| LP MR Compressor | MCL1405 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | Siemens 24 MW Synchronous Motor with VSD System |

| Power Generation | 5 x GE PG9171E DLN1 (Frame 9E) Gas Turbine Generators |

Refrigeration Train Configuration

Key Facts

- The original budget for Gorgon LNG Project was estimated at $37 billion in 2009. By 2012 the cost blow outs pushed the budget up to $52 Billion and by end of 2013 the figure had crossed $54 Billion, making the project almost 50% more expensive than originally planned.1

- The Gorgon LNG Project selected a modularization approach in order to minimise on-island work, reduce construction footprint and gain a cost advantage by employing world-class fabrication facilities in Indonesia, China and South Korea. Hyundai Heavy Industries fabricated the 51 process modules, weighing a total of 230,000 tons, in Ulsan, Korea. PT McDermott, Indonesia and Chinese Offshore Oil Engineering Company (COOEC) put together 236 pre-assembled racks and units. The heaviest module is 55 metres long, 46 metres wide, 45 metres high and weighs 6300 tonnes.2,3

- When Gorgon received its initial FID, it planned to harness the 50 trillion cubic feet natural gas reserves from the Greater Gorgon over 60 years, however subsequent discoveries in 2012 & 2013 added another 7 trillion cubic feet natural gas reserves to the available resources.4

- The natural gas from the Greater Gorgon fields was tested as high quality with low sulphur and carbon dioxide content, however, Gorgon project owners decided to capture the greenhouse gas and reinject it into the ground, to reduce the carbon footprint of the project.4

- In May 2016, Chevron received environmental approval for Train 4. The approval is valid till January 1, 2070, however, it comes with numerous environmental management, monitoring, and reporting conditions.5

- Gorgon LNG has an unfortunate history of unplanned shutdowns. In March 2016, 18 days after Gorgon produced its first LNG, failure of a knockout drum that removes remnant propane liquid, damaged the Train 1 compressor and triggered a 3 month expensive outage. In July 2016, a gas leak necessitated unexpectedly closure and evacuation of the plant. In November 2016, Train 1 production was again halted due to performance variations.6,7,8,9

- In addition to the unplanned outages, Gorgon LNG experienced multiple planned shutdowns. Train 2 production was suspended in March 2017 to enhance the train’s reliability and again in May 2017 for performance improvement modifications. This became the 8th outage at the plant in 14 months. 10,11,12

- Train 3 came online in March 2017, but had to be shutdown in November 2017 for planned maintenance. In mid-January 2019, a mechanical snag in the LNG’s cooling process due to strong heatwaves in Australia, resulted in another unfortunate shutdown.13,14

- Gorgon LNG employs four second generation Svitzer’s Ecotug® vessels. The Diesel-Electric Hybrid tugs, with electrical deck equipment, low-reflection paint, double wall fuel tanks, solar panel water heating and on-board water recycling, are designed for lower noise, light emissions and fuel consumption. Svitzer claims that the 33m long, 13m wide and 75 Tonne Bollard Pull (TBP) eco-friendly tugs are ideally suited for operations in one of Australia’s most environmentally sensitive regions.15

- The jetty at Barrow Island was built by CIMIC and Saipem, in 2012, Saipem agreed to changes in the scope of work. In February 2016, CIMIC claimed $1.86 billion plus $500 million in interest and costs for the cost blow-outs. The dispute negotiations were followed by arbitration. 16,17

Source:

1. ‘Chevron reveals second Gorgon gas project cost blowout, ABC News Website, 12 Dec 2013

2. Young W.S. ‘Gorgon Project Downstream Execution Overview’, Chevron Website, 25 September 2012

3. ‘Chevron-operated Gorgon Project’, KBR Website

4. ‘Chevron harvests gas discoveries in Australia Greater Gorgon’, 2b1st Consulting Website, 15 May 2013

5. ‘Chevron wins environmental approval for Gorgon LNG Train 4’, LNG World News Website, 31 May 2016

6. ‘Chevron sets date for first Gorgon LNG cargo after shutdown’, LNG World News Website, 27 June 2016

7. ‘Chevron says resumes Gorgon LNG production’, LNG World News Website, 23 July 2016

8. ‘Chevron resumes production at Gorgon LNG Train 1’, LNG World News Website, 4 January 2017

9. Milne P. ‘The day disaster struck Gorgon’, The West Australian Website, 10 April 2017

10. Murtaugh D. et al. ‘Chevron’s $54 Billion LNG Plant Hits New Snag in Australia’, Bloomberg Website, 16 May 2017

11. ‘Chevron suspends Gorgon LNG Train 2 production’, LNG World News Website, 27 March 2017

12. ‘Chevron to shut 2nd Gorgon LNG train in May’, LNG World News Website, 1 May 2018

13. ‘Chevron shuts down Gorgon LNG Train 3 for maintenance’, LNG World News Website, 16 November 2017

14. ‘Chevron’s (CVX) Gorgon LNG Train 3 Hit by Mechanical Snag’, Nasdaq Website, 17 January 2019

15. ‘Svitzer Ready to Serve Gorgon LNG, Australia’s Largest Single Resource Project’, Svitzer Website, 13 April 2015

16. ‘Saipem Agrees to Changes in Scope of Work on Gorgon LNG, Australia’, LNG World News Website, 27 June 2012

17. ‘CIMIC’s Gorgon dispute pushed back two years’, The West Australian Website, 18 July 2017