In 2004, the Wheatstone offshore gas resource was discovered by Chevron Australia and in March 2008 they announced their intent to develop an LNG plant in conjunction with an onshore facility located at the Ashburton, 7.4 miles (12 km) west of Onslow in Western Australia’s Pilbara region. The Wheatstone Project’s offshore processing platform is located in 70 metres of water, about 225km from the coast.

The construction of the project commenced in 2011 to develop two LNG trains with a combined capacity of 8.9 million metric tonnes per annum (MMTPA). Delays in construction resulted in an increase of project costs to $34 billion from the original estimate of $29 billion.1 The plant with a design lifespan of 30 years, witnessed its first LNG production and shipment in October 2017. The second train at Wheatstone was started successfully in June 2018. Approximately 85 percent of Chevron’s LNG from its Western Australian LNG projects is already covered by sales and purchase agreements with premier customers.2

Wheatstone LNG is one of Australia’s largest resource developments and the nation’s first liquefied natural gas (LNG) hub. At full capacity, the Project can contribute around six percent of the Asia Pacific region’s total future LNG production!3 The offshore facilities gather gas from the Wheatstone, Iago, Julimar and Brunello gas fields. The gas and associated condensate are partially processed and then transported onshore via a trunkline for further processing. In addition to LNG and condensate, the plant can produce 200 terajoule of domestic gas per day, making Chevron Australia a major supplier of domestic gas in Western Australia.

The Wheatstone Project claims to have generated more than 7,000 jobs in Australia, in addition to spending more than $455 million with local Onslow businesses and organisations. They have also committed more than $250 million to social infrastructure projects in Onslow4. Stringent environmental guidelines have resulted in a range of environmental monitoring and management programs, which are in place at Wheatstone to protect marine fauna and sensitive benthic habitats.2

OWNERSHIP (Equity %)

| Chevron Australia | 64.14% |

| Kuwait Foreign Petroleum Exploration Company (KUFPEC) | 13.40% |

| Woodside Petroleum Limited | 13.00% |

| Kyushu Electric Power Company | 1.46% |

| PE Wheatstone Pty Ltd, part-owned by JERA | 8.00% |

General Data

| Estimated Capital Cost (USD) | 17B per Train |

| Plant Type | Onshore Modular |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2011 |

| FEED Contractor | Bechtel |

| EPC Contractor | Bechtel |

| No. of Trains / capacity | 2 Trains / 4.45 MMTPA each |

| Production Start Year | 2017 (Train 1) 2018 (Train 2) |

| Products | LNG, Condensate |

| Gas Type | Non-Associated Gas (NAG) |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | CoP Optimized Cascade® |

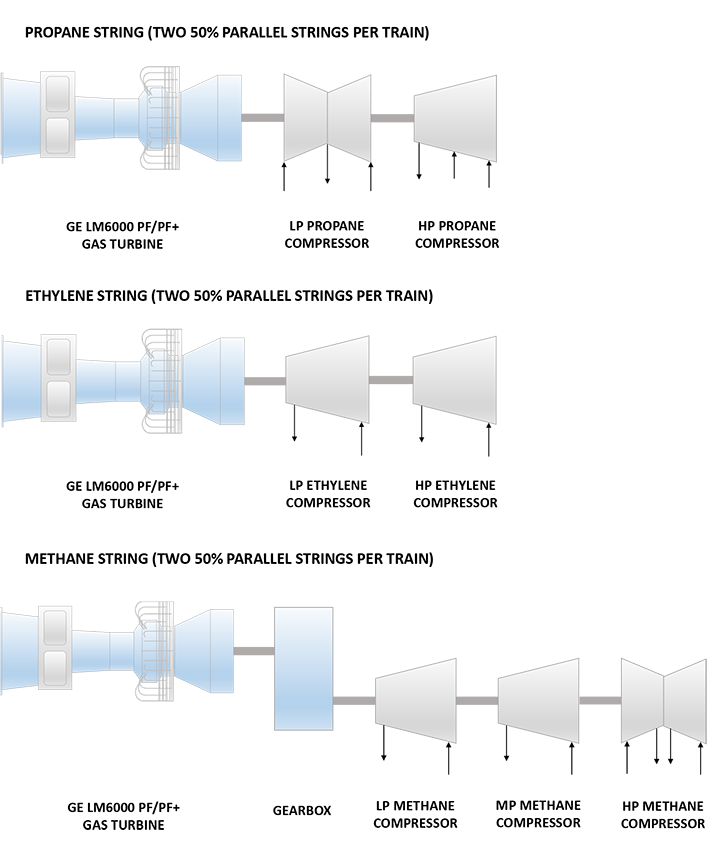

| Refrigeration Train Details: | |

| Propane Strings 1 & 2 | |

| Driver | GE LM6000 PF/PF+ DLE Aeroderivative Gas Turbine |

| LP Propane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| HP Propane Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| Ethylene Strings 1 & 2 | |

| Driver | GE LM6000 PF/PF+ DLE Aeroderivative Gas Turbine |

| LP Ethylene Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| HP Ethylene Compressor | GE (Nuovo Pignone) Centrifugal Compressor |

| Methane Strings 1 & 2 | |

| Driver | GE LM6000 PF/PF+ DLE Aeroderivative Gas Turbine |

| LP Methane Compressor | MCL805 GE (Nuovo Pignone) Centrifugal Compressor |

| MP Methane Compressor | MCL806 GE (Nuovo Pignone) Centrifugal Compressor |

| HP Methane Compressor | 2BCL608 GE (Nuovo Pignone) Centrifugal Compressor |

Refrigeration Train Configuration

Key Facts

- The name Wheatstone comes from the Wheatstone Channel in the Montebello Islands, an archipelago of 174 small islands 130km off the Pilbara coast.2

- Wheatstone LNG is Australia’s first natural gas hub.5

- The Wheatstone platform is the largest offshore gas-processing platform ever installed in Australia, with a topside weight of about 37,000 metric tons, and the largest float-over installation Chevron has ever delivered globally.5

- Wheatstone LNG is the first LNG plant in the world to use GE’s LM6000 PF aeroderivate gas turbines as the refrigeration compressor drivers.6 It is also the first ever mechanical drive application of the LM6000 PF+ gas turbines.

- Technip was the FEED contractor for the offshore processing platform. INTECSEA was the FEED contractor for the subsea systems, flowlines and pipelines scope. Prior to award of this contract, INTECSEA was assisting in “pre-FEED” activities for the Wheatstone Project while working in partnership with WorleyParsons Select and Granherne as part of the SGI joint venture.7

- More than $250 million has been committed to social and critical infrastructure projects in Onslow, which include upgrading community facilities, education and health services, roads, and power and water infrastructure.8

Source:

1. https://www.lngworldnews.com/chevrons-wheatstone-lng-project-to-cost-us5-billion-more-woodside-plays-down-impact/

2. https://www.chevron.com/-/media/chevron/projects/documents/fact-sheet-wheatstone-project-overview.pdf

3. https://australia.chevron.com/news/2017/first-chevron-wheatstone-lng-cargo-departs-for-japan

4. https://australia.chevron.com/community/chevron-in-onslow

5. https://www.chevron.com/projects/wheatstone

6. Full Speed String Test on GE LM6000PF Gas Turbine Driven Refrigeration Compressors, 45th Turbomachinery & 32nd Pump Symposia, 2016 (http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/159792/01_Patwardhan.pdf?sequence=1)

7. https://www.epcengineer.com/projects/details/111/wheatstone-lng-project/profile

8. https://www.euro-petrole.com/first-chevron-wheatstone-lng-cargo-departs-for-japan-n-i-15668