Sakhalin-II was the outcome of Russia’s first production sharing agreement (PSA), which was signed in 1994 as a joint venture between Royal Dutch Shell, Mitsui, Mitsubishi and the Russian government. In August 2003, construction of an LNG plant commenced at Prigorodnoye in Aniva Bay on Sakhalin Island, in the North Pacific Ocean. Sakhalin is Russia’s largest island and is administered as part of Sakhalin Oblast. Two pipelines, 800 kms each were built to supply oil and gas from the fields in the north of the island to the ice-free location of the facility1. The first LNG sale and purchase agreement (SPA) was signed on 9th June 2004 with Kyushu Electric Power Company for a period of 20 years. Multiple agreements were subsequently signed with several buyers between 2005 and 2009. 98% capacity of the plant was spoken for by the time the SPA with Osaka Gas was signed on 4th March 2009.2

The consortium came under severe reproach for environmental non-compliance, resulting in an order by the Russian government to terminate the project in September 2006. This necessitated the sale of a majority share to state controlled Gazprom in 2007.3 On 18th February 2009, Sakhalin-II became the first LNG plant to be operational in Russia. The facility operated by Sakhalin Energy Investment Company Ltd. (Sakhalin Energy) consists of 2 trains, of nameplate capacity 4.8 MMTPA each. The frigid conditions required Shell to develop a special gas liquefaction process using double mixed refrigerant for Sakhalin-II.4

At the end of March 2009, the first cargo was shipped aboard LNG carrier Grand Aniva. The plant currently caters to 4% of the world’s LNG market, with main customers in Japan, South Korea and China. A memorandum to build a third train at the facility was signed between Shell and Gazprom in June 2015, progress on this has been impeded due to recent sanctions imposed on Russia.5 In 2017, Sakhalin-II produced 11.49 million tons of LNG, well in excess of the original plant capacity.4 In June 2018, Sakhalin II shipped its 1500th LNG Cargo.

The Sakhalin project claims to have delivered significant benefits to the region, which include local infrastructure development, education, healthcare and safety along with concern for indigenous minorities, biodiversity and environmental protection. Gazprom aids numerous initiatives for development of culture, science, education and healthy lifestyle.7

OWNERSHIP (Equity %)

| Gazprom Sakhalin Holdings B.V. | 50.00% |

| Shell Sakhalin Holdings B.V. | 27.50% |

| Mitsui Sakhalin Holdings B.V. | 12.50% |

| Mitsubishi Corporation | 10.00% |

General Data

| Estimated Capital Cost (USD) | 10 B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2003 |

| FEED Contractor | Chiyoda Corporation |

| EPC Contractor | Chiyoda Corporation Toyo Engineering Corporation |

| No. of Trains / capacity | 2 Trains / 5.4 MMTPA each |

| Production Start Year | 2009 |

| Products | LNG,Condensate |

| Gas Type | Associated Gas |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | Shell DMR |

| Refrigeration Train Details: | |

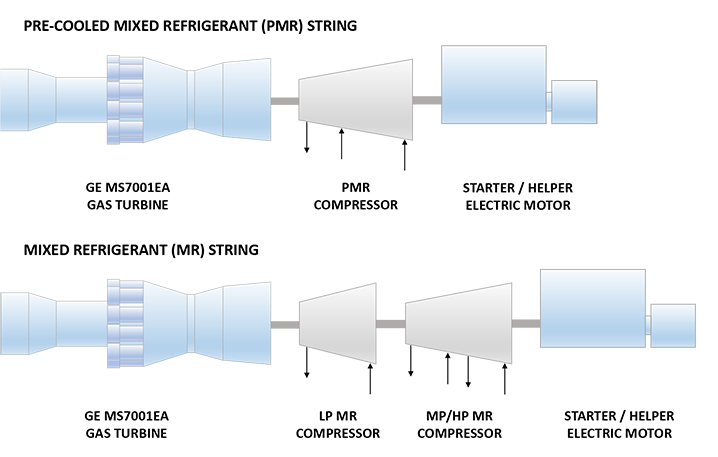

| Pre-cooled Mixed Refrigerant (PMR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| PMR Compressor | 88MB6-5 Elliott Radially Split Centrifugal Compressor |

| Starter/Helper Motor | Siemens 12 MW Synchronous Motor with LCI Drive |

| Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA DLN1 (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) MR Compressor | AV71-16 MAN Turbo Axial Compressor |

| Medium Pressure (MP) / High Pressure (HP) MR Compressor | 60MB6I Elliott Radially Split Centrifugal Compressor |

| Starter/Helper Motor | Siemens 12 MW Synchronous Motor with LCI Drive |

| Power Generation | 5 x GE MS5001P Heavy Duty Gas Turbines |

Refrigeration Train Configuration

Key Facts

- Sakhalin II is built at a high seismic area with a hostile subarctic environment. Significant engineering innovation was required to make Sakhalin II earthquake-resistant. The onshore and offshore platforms are designed to resist loads caused by earthquakes using slide-type legs. The project pioneered the use of a cradle mechanism (sliding pendulum bearings) between the topsides (weighing 28,000 tonnes) and the concrete-reinforced bases to ensure safe operation of the offshore platforms. In case of an earthquake, the legs allow the topsides to sway smoothly on hinges, thereby preventing the destruction of the whole structure. The technology used was a first for the oil and gas industry.4

- Sakhalin II is the first application of Shell’s Double Mixed Refrigerant (DMR) liquefaction technology. This technology was selected to maximize the production efficiency in the extreme cold of Sakhalin’s winters, where temperatures are often as low as -35°C. A DMR technology plant requires 6 to 9% less energy in the process cycle compared to other bench-marked plants, which benefits specific energy consumption. The DMR process also has a lower total equipment count compared with other similar capacity technologies due to the use of mixed refrigerant in the pre-cooling stage.8

- The LNG plant was built on a 490-hectare site at Prigorodnoye, Aniva Bay, 13km east of Korsakov. The facility has two LNG storage tanks of 100,000m³ capacity and LNG is exported from an 805m jetty in Aniva Bay with two loading arms and one boil-off gas return arm.10

- In 2007, Gazprom and the shareholders of Sakhalin Energy (Royal Dutch Shell, Mitsui & Co., and Mitsubishi Corporation), the Sakhalin II project operator, signed the Purchase and Sale Agreement providing for Gazprom to acquire a stake of 50% plus one share in Sakhalin Energy.12

- The LNG plant reached full capacity in 2014 and subsequently exceeded its annual design output by producing more than 10 million tonnes of liquefied natural gas. Since then it has continued in its streak of increasing production and produced 10.93 million tonnes in 2016 and 11.49 million tonnes in 2017 which has been the highest recorded since 2009.14

- Production system optimization and cryogenic heat exchanger modifications at the two liquefaction trains resulted in a 12.5% increase of the installed production capacity. Also, an addition of wind screens around the air coolers of the two LNG trains as part of modifications in 2017 helped reduce the impact of hot air circulation caused by crosswind on the cooling process giving an annual increase of 0.5% of LNG production with maximum impact in summer months.14

- On March 26, 2017, a gas leak accident suspended the operation of the plant abruptly though the leak was contained.15

- The long-awaited Sakhalin expansion came into force when Gazprom and Shell signed a deal to start construction of third train with a capacity of 5.4 MMTPA in June 2015. The FEED awarded to Shell Global Solutions International and Giprogazcenter, a Russian design institute neared completion between 2016 and 2017 but its fate still dwindles on gas supplies and is reported to dependent on the South Kirinskoye offshore field, so delay is expected to stretch till 2019. However, an ambition for the fourth train is also underway and the plant is looking to source gas from the Eosnef-ExxonMobile and Yuzhno-Kirinskoye deposit.16

- In July 2005, a petition was filed by environmentalists over Sakhalin Energy’s environmental impact assessment. Though the appeal was upheld by court and came to an end in November 2005, the World Wildlife Fund (WWF) expressed its concerns regarding declining gray whale populations, regular oil spills, the death of birds, water pollution, and others related to the plant.17

Source:

1. ‘Sakhalin II Phase 2 cost estimate rising’, Oil & Gas Journal Website, 14 July 2005

2. ‘Sakhalin II Signs a Full-Scale LNG Supply Deal with Osaka Gas’, Sakhalin Energy Website, 4 March 2009

3. Bowers S. ‘Sakhalin issues ‘settled’ – as Russia takes 50% stake’, The Guardian, 22 December 2006

4. ‘Project Implementation’, Gazprom Projects Website

5. Astrasheuskaya N. et al ‘Russian natural resources ministry admits sanctions are biting on natural gas projects’, SP Global Website, 17 August 2018

6. ‘Sakhalin-2’, Gazprom Export Website

7. ‘Social Initiatives’, Sakhalin Energy Website

8. Nored M. et al, ‘A Historical Review of Turbomachinery for LNG Applications’, 17th International Conference and Exhibition on Liquefied Natural Gas 2013 (LNG 17), 2013

9. ‘Russia’s Sakhalin 2 Project to Go Ahead’, Rigzone NEWS Website

10. ‘Sakhalin II Crude Oil and Liquified Natural Gas, Sakhalin Island, Russia’, Hydrocarbons Technology Website

11. Flatøy R. and Johansen K. ‘Living Next Door to Gazprom’, Bodø Graduate School of Business and MGIMO University, Moscow, 23 May 2007

12. ‘Gazprom, Shell Discuss Sakhalin II Project (Russia)’, LNG World News Website, 16 March 2012

13. ‘Sakhalin Energy and Sovcomflot extend cooperation’, LNG World News Website, 7 July 2014

14. ‘Russia’s Sakhalin LNG plant continues to produce at record rates’, LNG World News Website, 28 September 2017

15. ‘Production halted at Russia’s only LNG export plant’, LNG World News Website, 27 March 2017

16. Multiple Sources:

> ‘Gazprom, Shell sign Sakhalin LNG expansion deal’, LNG World News Website, 18 June 2015

> ‘Gazprom eyeing fourth LNG train at Sakhalin-2’, LNG World News Website, 29 September 2015

> ‘Design contract awarded for Sakhalin II’s third LNG train’, LNG World News Website, 18 December 2015

> ‘Sakhalin 2’s third train may depend on South Kirinskoye’, Upstream Online Website, 14 June 2018

17. World Wildlife Fund ‘Sakhalin II – The Truth Uncovered’, March 2006