On May 17, 1989 Nigeria LNG Limited was established to tap Nigeria’s abundant natural gas resource and monetise it through LNG exports. Final Investment Decision (FID) for the first 2 trains was receivedin November 1995. Construction started on the 2.27 square kilometre of mostly reclaimed land at Finima, Bonny Island in 1996. Train 2 was the first to be set for start-up and production was underway in September 1999. Train 1 was started production in February 2000.

Riding on the success of the 2 trains, subsequent expansion plans were deployed rapidly. Train 3 received FID in February 1999 and came on stream in November 2002. Under the NLNG Plus project, construction of 2 additional trains was initiated in March 2002, leading to Train 4 commencing operation in November 2005 and Train 5 joining in by February 2006. The NLNG Six project included construction of a condensate processing and LPG storage facility in addition to the added capacity ofTrain 6, which commenced operations in December 2007.

The plant boasts of a diversified gas supply (Associated Gas & Non-Associated Gas) and six main dedicated gas transmission pipelines with four of them on-shore. The 3.5 billion Bcf/day feed to the plant is supplied through long term Gas Supply Agreements (GSAs) with Shell Petroleum Development Company of Nigeria Limited (SPDC), Total Exploration Production Nigeria (TEPNG) and Nigerian Agip Oil Company Limited (NAOC). With a mammoth investment of $11 billion, the NLNG project boasts of 6 trains, 4 LNG storage tanks, 3 condensate storage tanks, 4 LPG refrigerated storage tanks and 10 gas turbine electricity generators with a combined output of 320 MW. The plant has a fleet of 23 LNG vessels that visit the 2 export jetties at the facility, which handles over 400 loadings per year. By May 2017 the plant had already shipped its 4000th cargo.

16 long term LNG Sales Purchase Agreements (SPAs) with 11 buyers consume the plant’s capacity of 22 MMTPA LNG in addition to 5 MMTPA NGL’s (LPG and condensate). The list of buyers includes Enel, Gas Natural, Botas, GDF Suez, GALP Gas Natural, BG LNG, Endesa, ENI, Iberdrola, Shell Western LNG BV and Total Gas and Power Ltd. Recent signing of a 20-year SPA with Total has prompted progress on the plans for the next phase of expansion. The addition of train 7 will enhance the total production capacity to over 30 MMTPA of LNG.

Each construction year generated in excess of 2000 jobs, while 18,000 locals were hired by the major sub-contractors for technical jobs in the base project. The company has initiated the Nigerianisationscheme, under which the company recruits, trains and develops skills of Nigerians for management, supervisory and operational positions in the company. NLNG’s social commitment extends to a range of other activities including health schemes, electricity generation, construction of roads, water projects and building educational infrastructure.

The company has initiated social welfare programs such as the Youth Empowerment Scheme (YES), the Nigeria LNG Agro Development Action (N- AGENDA), the Nigeria Prizes, NLNG University Scheme Programme, Micro-Credit etc. Over 200,000 residents receive uninterrupted power from NLNG Limited. NLNG has created a nature park on over 1000 hectares on Bonny Island with the view to preserve the natural environment of its host communities. Gas consumed by the plant helps in reducing flaring by upstream operators from 60% to below 25%.

OWNERSHIP (Equity %)

| Nigerian National Petroleum Corp. (NNPC) | 49.00% |

| Shell | 25.60% |

| Total | 15.00% |

| Eni | 10.40% |

General Data

| Estimated Capital Cost (USD) | Train 1 & 2 : 3.6 B Train 3 : 1.8 B |

| Plant Type | Onshore Stick-built |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | Train 1 & 2 – 1995 Train 3 – 1999 |

| FEED Contractor | KBR |

| EPC Contractor | Technip Snamprogetti KBR (formerly, M.W. Kellogg) Japan Gas Corporation |

| No. of Trains / capacity | 3 Trains / 3.3 MMTPA each |

| Production Start Year | 1999 (Train 1) 2000 (Train 2) 2002 (Train 3) |

| Products | LNG, LPG, Condensate |

| Gas Type | Associated & Non-Associated Gas |

Technical Data

| Cooling Media | Fresh Water (Cooling Tower) |

| Liquefaction Technology | APCI AP-C3MR™ |

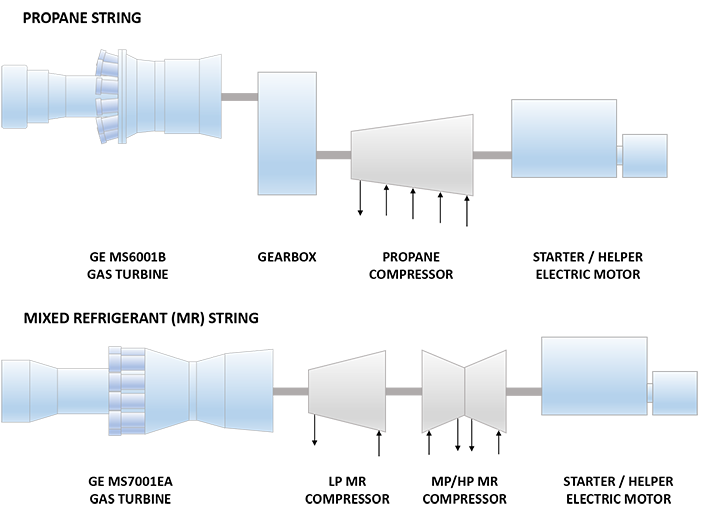

| Refrigeration Train Details: | |

| Propane String | |

| Driver | GE PG6551B (Frame 6B) Heavy Duty Gas Turbine |

| Gearbox | Double Helical Speed Reduction Gear box |

| Propane Compressor | Trains 1-2: Dresser-Rand Radially Split Centrifugal Compressor Train 3: 3MCL1405 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Starter/Helper Motor | 8 MW Electric Motor with VSD System |

| Mixed Refrigerant (MR) String | |

| Driver | GE MS7121EA (Frame 7EA) Heavy Duty Gas Turbine |

| Low Pressure (LP) MR Compressor | Trains 1-2: AV71-15 MAN Turbo Axial Compressor Train 3: AN200 GE (Nuovo Pignone) Axial Compressor |

| Medium Pressure (MP) / High Pressure (HP) MR Compressor | Trains 1-2: Dresser-Rand Radially Split Centrifugal Compressor Train 3: 2BCL806 GE (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Starter/Helper Motor | 8 MW Electric Motor with VSD System |

| Power Generation | 6 x GE PG6581B (Frame 6B) Heavy Duty Gas Turbines |

Refrigeration Train Configuration

Key Facts

- The very first LNG project proposed in Nigeria faltered in the early 1960’s. Subsequent efforts to build an LNG plant in Nigeria were also unsuccessful. Nigeria LNG Limited (NLNG) was formed in May 1989 and despite robust economics and a shareholder commitment, NLNG failed to raise non-recourse debt until the mid-nineties due to lack of political backing and an uncertain outlook for gas prices at the time.6

- The plant has constantly expanded in phases. The Base project came into effect in 1996 and included the Plant (consisting of Trains 1 and 2), the Gas Transmission System (GTS) and the Residential Area. The Expansion Project was the second development that was started in 1999 and included Train 3 and the plant’s condensate stabilization system.2

- The country is ranked ninth in terms of proven natural gas reserves in the world. The natural gas reserves are estimated to be sufficient to sustain current production rates for over 60 years.3

- NLNG Trains 1 & 2 is estimated to have cost USD 2.1 billion. Train 3 expansion included an additional LNG tank and cost approximately USD 1.8 billion. Train 3 was financed through equity contributions by the shareholders with revenue and surpluses from the Base Project being re-invested. However, a majority of the cost of the new LNG tankers was borne by third party financiers which when secured in 2002, represented the single largest lending to an industrial complex in sub-Sahara Africa.3

- NLNG has a total of 23 LNG vessels on long-term time charter for its six-train operation, and one domestic LPG vessel. LPG vessels are utilized for LPG delivery in the Nigerian market.

- On Train 3, very high amplitudes of vibration were measured on the suction piping of the LP MR Compressor (AN200 axial compressor). The vibrations were found to be a result of periodic vortex shedding at the trailing edge of the inlet guide vane segments (in the piping upstream of the compressor) coupled with acoustic resonance, exciting the suction pipe wall. The issue was resolved by adding metal strips between the vane segments to close any open slots between the segments thereby preventing the phenomenon from occurring.11

- For Train 3 construction, KBR reported 44+ million man-hours without a Lost Time Incident (LTI).5

- In August 2005, a 28-inch underground pipe supplying feed gas to Nigeria LNG, exploded at Kalakama, Ogoloma Fishing Community in Okrika Local Government Area of Rivers State. The incident is reported to have taken 11 lives and resulted in a wild inferno which engulfed an estimated 27 sq. kms destroying the mangroves, cash crops and marine life in its surroundings forcing the closure of Trains 2 and 3.8

- LNG exports were affected again in 2017 when a gas pipeline supplying the plant exploded. There were no reported injuries and operations resumed in March 2017. The cause of the explosion remained unknown.9

Source:

1. ‘NLNG: Major Milestones’, NLNG Website

2. ‘The Plant’, NLNG Website

3. Publications ‘Facts and Figures on NLNG 2018’, NLNG Website

4. ‘Shipping’, NLNG Website

5. ‘Nigeria LNG (NLNG) Train 3 Project Profile’, KBR Website

6. Blanc-Brude F. ‘Is Nigeria Liquid? Financing Nigeria LNG+’, Infrastructure Journal Website, 2003

7. Amaechi J. et al ‘A study of the environmental impact of the Liquefied Natural Gas (LNG) Company on the environment’, International Scholars Journals Website, 2 December 2016

8. Okocha C. ‘11 Feared Dead in LNG Pipeline Explosion’, All Africa Website, 3 September 2005

9. ‘NLNG to resume gas supply after pipeline explosion’, Premium Times NG Website, 13 March 2017

10. Jamieson A. et al ‘Nigeria LNG – Overcoming Technical and Commercial Challenges To Become One Of The World’s Major Exporters Of LNG’, 14th International Conference & Exhibition on Liquefied Natural Gas Doha, Qatar, 2004

11. Smeulers J. et al ‘Flow Induced Vibrations‘, LNG Industry, 2006