In 1954, Santos was founded, with its name derived from the acronym for South Australia Northern Territory Oil Search. In 1963, the company made its first major discovery of natural gas in the Cooper Basin. In the 1980’s, Santos keenly developed a major liquids business and by 1990’s it was a sprawling enterprise with interests in multiple petroleum provinces. The unfortunate earthquake and tsunami, that led to a meltdown at the Fukushima Nuclear reactor in 2011, triggered a near-complete shutdown of Japan’s nuclear power capabilities, which at the time accounted for 30% of Japanese generating capacity. This triggered a boom in LNG demand and in many ways contributed to the sanctioning of the Gladstone LNG (GLNG) project along with 2 other projects in the region.

The GLNG project owned by Santos, Petronas, Total and KOGAS, is built on Curtis Island in Queensland, Australia on the edge of the Great Barrier Reef. The plant consumes Coal Seam Gas (CSG) resources from Surat and Bowen basins in south-east Queensland, which is brought on-shore through a 420-kilometer underground gas transmission pipeline. The maiden cargo from the first train was shipped on 16 October 2015, while the second train started production on 26 May 2016. The 2 trains have a combined capacity of 7.8 MMTPA, almost all of which is committed through sales and purchase agreements with PETRONAS and KOGAS.

In recent years, abundant availability of gas has triggered multiple plants being commissioned in the United States and several other countries worldwide. This has led to oversupply in the LNG market, which when compounded with the high capital costs of Australian LNG plants and the excessive operating costs of the CSG fields, has raised serious questions on the competitiveness of LNG exports from Gladstone.1 Depletion of traditional east coast reserves, which catered to the domestic gas demand, now threatens diverting CSG from export to domestic use.2 In July 2017, the Australian Government introduced the Australian Domestic Gas Security Mechanism (ADGSM), which has the power to restrict LNG exports from Gladstone to protect local supply.3 In June 2017, the Institute for Energy Economics and Financial Analysis (IEEFA) made a shocking prediction, which forecasted production shutdown at GLNG within 2 years.4

Santos focusses its community investment strategy on shared outcomes, education and community vibrancy, this includes caring for the natural environment (land, air and water projects), developing a future for young people & the region and investing in community health. The GLNG project invested $210 million to upgrade rural roads in the region. The company works with Aboriginal communities and offers employment, training, education and enterprise opportunity.

The company’s Environment, Health and Safety Management System (EHSMS) covers multiple aspects including improving air quality, protecting biodiversity and land, climate change performance, prevention of incidents and spills, efficient waste management and the protection and management of water resources. Santos is involved with various initiatives such as the Witchelina Nature Reserve, research on southern right whales in the Great Australian Bight and securing 25,700 hectares of land on Curtis Island for conservation and protection, in cooperation with 2 other LNG projects in the area.

OWNERSHIP (Equity %)

| Santos Limited | 30.00% |

| PETRONAS | 27.50% |

| Total | 27.50% |

| KOGAS | 15.00% |

General Data

| Estimated Capital Cost (USD) | 4.25B Per Train |

| Plant Type | Onshore Modular |

| Plant Stage | Operating |

| Final Investment Decision (FID) Year | 2011 |

| FEED Contractor | Foster Wheeler Bechtel |

| EPC Contractor | Bechtel |

| No. of Trains / capacity | 2 Trains / 3.9 MMTPA each |

| Production Start Year | 2015 (Train 1) 2016 (Train 2) |

| Products | LNG |

| Gas Type | Coal Bed Methane (CBM) |

Technical Data

| Cooling Media | Air |

| Liquefaction Technology | CoP Optimized Cascade® |

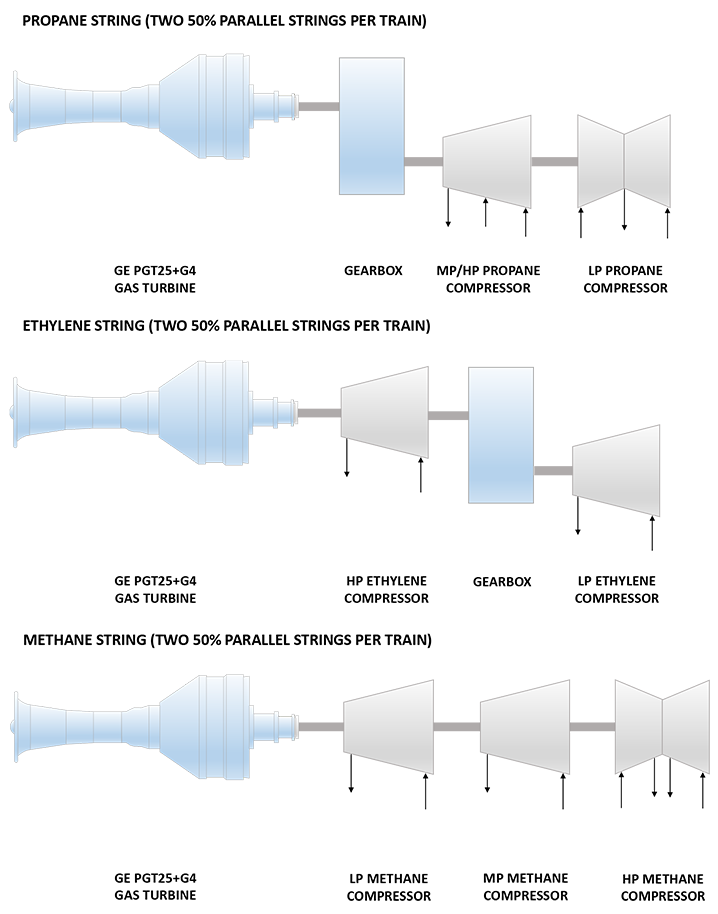

| Refrigeration Train Details: | |

| Propane Strings 1 & 2 | |

| Driver | GE PGT25+G4 DLE (with Inlet Air Chilling) Aeroderivative Gas Turbine |

| Gearbox | Double Helical Speed Reduction Gearbox |

| Medium Pressure (MP)/ High Pressure (HP) Propane Compressor | 3MCL1002 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Low Pressure (LP) Propane Compressor | DMCL1004 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Ethylene Strings 1 & 2 | |

| Driver | GE PGT25+G4 DLE (with Inlet Air Chilling) Aeroderivative Gas Turbine |

| High Pressure (HP) Ethylene Compressor | MCL804 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Gearbox | Double Helical Speed Reduction Gearbox |

| Low Pressure (LP) Ethylene Compressor | MCL1404 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Methane Strings 1 & 2 | |

| Driver | GE PGT25+G4 DLE (with Inlet Air Chilling) Aeroderivative Gas Turbine |

| Low Pressure (LP) Methane Compressor | MCL806 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| Medium Pressure (MP) Methane Compressor | MCL806 GE (Nuovo Pignone) Horizontally Split Centrifugal Compressor |

| High Pressure (HP) Methane Compressor | 2BCL607 E (Nuovo Pignone) Radially Split Centrifugal Compressor |

| Power Generation | 6 x Solar Titan 130 Gas Turbine Generators |

Refrigeration Train Configuration

Key Facts

- The shareholding of Gladstone LNG (GLNG) underwent a series of changes since the project’s conception by Santos in July 2007. In May 2008, PETRONAS came aboard as a 40% joint venture partner for an investment of USD 2 billion. In September 2010, Total of France acquired 15% from Santos and 5% from PETRONAS. Finally, in December 2010, KOGAS joined as a shareholder by acquiring 7.5% each from Santos & PETRONAS, while Total purchased an additional 7.5% stake from Santos, contributing USD 705.8 million to the development of the project. Currently, Santos holds 30%, PETRONAS and Total hold 27.5% each and KOGAS holds 15%.5

- Two FEED studies were conducted for GLNG. Bechtel based its FEED study on the ConocoPhillips Optimized Cascade® Process while Foster Wheeler’s was based on the APCI AP-C3MRTM process. Fluor was contracted for building upstream surface facilities, while Saipem was charged with construction of the gas transmission pipeline and John Holland for marine offloading facilities. The American engineering firm, AECOM was selected as Environmental consultants.5,6

- GLNG is an onshore modular plant with 111 modules, together tipping the scales at 44,000 metric tonnes. Atlantic, Gulf and Pacific Company of Manila Inc. (AG&P) was given the charge to build the modules for Bechtel. The largest module of Train 1 is the 2,500 tonnes chiller which is 48m long and 35m wide. 7,8

- In 2010, GLNG signed 20-year SPAs with PETRONAS of Malaysia and KOGAS of South Korea. PETRONAS agreed to purchase 3.5 MMTPA of LNG with 1.8 MMTPA supplied from Train 1 and 1.7 MMTPA from Train 2. KOGAS also purchased 3.5 MMTPA of LNG with 1.7 MMTPA supplied from Train 1 and 1.8 MMTPA from Train 2. These agreements are equivalent to approximately 9% of Malaysia’s and 11% of Korea’s domestic demand for LNG.9

- In July 2013, Santos, operator of the Gladstone LNG project, and BG Group subsidiary QGC (now Shell), which operates the Queensland Curtis LNG project, agreed to connect the two pipelines that feed their plants provide enhanced flexibility during the projects’ lifetimes. The move was regarded as the first of many cooperation deals. The interconnect will allow flow of gas between the projects when required, maximizing plant productivity, especially during scheduled and unscheduled down times.10

- Siemens received a 6-year contract from GLNG’s for preventative maintenance, remote monitoring, parts supply and field service for its 16 SGT-400 industrial gas turbines, 9 generator sets and 7 compressor sets. This became Siemens’ single largest service order for its small gas turbine line-up.11

- The first cargo from GLNG was shipped to KOGAS’ Incheon LNG terminal in South Korea onboard MISC Berhad operated 152,300m3 “Seri Bakti”.12

- In 2014, Saipem was awarded Queensland Government’s Premier’s Sustainability Award for Innovation in Sustainable Technologies, demonstrated by designing and constructing the 4.3km long and 42-inch wide Narrows Marine Crossing, which is one longest trenchless marine pipeline in the world. Saipem used Tunnel Boring Machine and Pipe Thruster Machine to build a 4 meters wide undersea tunnel that would carry the pipeline across the vast tidal plains, without disturbing local marine habitat, wildlife and neighbouring coastal environment.13

Source:

1. Robertson B. ‘Australia’s Export LNG Plants at Gladstone: The Risks Mount’, Institute for Energy Economics and Financial Analysis Website, June 2017

2. Browne N. ‘LNG Changes Everything For Australia’s East Coast Gas Market’, Forbes Website, 12 July 2018

3. ‘Australian gas shortages loom as LNG exporters and domestic consumers compete for supply’, Wood Mackenzie Website, 11 September 2018

4. Robertson B. ‘First Australian export LNG plant could close within 3 years’, Renew Economy Australia Website, 6 June 2017

5. ‘Gladstone Liquefied Natural Gas Project’, Hydrocarbons Technology Website

6. ‘John Holland Gets GLNG Contract’, LNG World News Website, 23 March 2011

7. ‘Santos GLNG Project Hits Milestone’, LNG World News Website, 3 April 2014

8. ‘Gladstone LNG Project – Liquefaction Train Modularization’, AGP Philippines Website, November 2018

9. ‘The LNG industry GIIGNL Annual Report 2018’, GIIGNL Website, 2018

10. ‘Santos GLNG and QGC sign industry collaboration deal’, Santos Website, 4 July 2013

11. ‘Siemens awarded long-term service agreement for Santos GLNG Project in Australia’, Siemens Website, 10 May 2012

12. ‘First GLNG cargo on way to South Korea’, LNG World News Website, 16 October 2015

13. ‘Saipem wins 2014 Premier’s Sustainability Award for Innovation in Sustainable Technologies in Australia’, Euro-petrole Website, 23 June 2014